Page 173 - Handbook of Surface Improvement and Modification

P. 173

168 The Coefficient of Friction

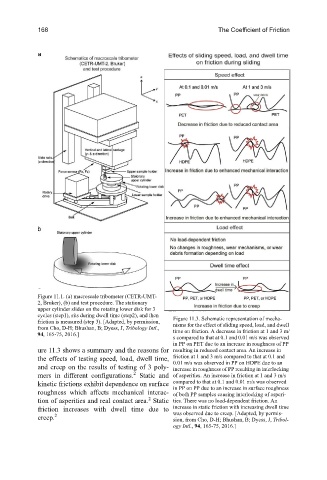

Figure 11.1. (a) macroscale tribometer (CETR-UMT-

2, Bruker), (b) and test procedure. The stationary

upper cylinder slides on the rotating lower disk for 3

cycles (step1), sits during dwell time (step2), and then Figure 11.3. Schematic representation of mecha-

friction is measured (step 3). [Adapted, by permission, nisms for the effect of sliding speed, load, and dwell

from Cho, D-H; Bhushan, B; Dyess, J, Tribology Intl., time on friction. A decrease in friction at 1 and 3 m/

94, 165-75, 2016.]

s compared to that at 0.1 and 0.01 m/s was observed

in PP on PET due to an increase in roughness of PP

ure 11.3 shows a summary and the reasons for resulting in reduced contact area. An increase in

the effects of testing speed, load, dwell time, friction at 1 and 3 m/s compared to that at 0.1 and

and creep on the results of testing of 3 poly- 0.01 m/s was observed in PP on HDPE due to an

increase in roughness of PP resulting in interlocking

2

mers in different configurations. Static and of asperities. An increase in friction at 1 and 3 m/s

kinetic frictions exhibit dependence on surface compared to that at 0.1 and 0.01 m/s was observed

roughness which affects mechanical interac- in PP on PP due to an increase in surface roughness

of both PP samples causing interlocking of asperi-

2

tion of asperities and real contact area. Static ties. There was no load-dependent friction. An

friction increases with dwell time due to increase in static friction with increasing dwell time

2

creep. was observed due to creep. [Adapted, by permis-

sion, from Cho, D-H; Bhushan, B; Dyess, J, Tribol-

ogy Intl., 94, 165-75, 2016.]