Page 89 - Handbook of Surface Improvement and Modification

P. 89

84 Tackifiers

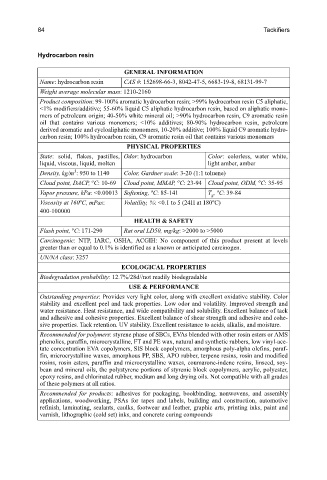

Hydrocarbon resin

GENERAL INFORMATION

Name: hydrocarbon resin CAS #: 152698-66-3, 8042-47-5, 6683-19-8, 68131-99-7

Weight average molecular mass: 1210-2160

Product composition: 99-100% aromatic hydrocarbon resin; >99% hydrocarbon resin C5 aliphatic,

<1% modifiers/additive; 55-60% liquid C5 aliphatic hydrocarbon resin, based on aliphatic mono-

mers of petroleum origin; 40-50% white mineral oil; >90% hydrocarbon resin, C9 aromatic resin

oil that contains various monomers; <10% additives; 80-90% hydrocarbon resin, petroleum

derived aromatic and cycloaliphatic monomers, 10-20% additive; 100% liquid C9 aromatic hydro-

carbon resin; 100% hydrocarbon resin, C9 aromatic resin oil that contains various monomers

PHYSICAL PROPERTIES

State: solid, flakes, pastilles, Odor: hydrocarbon Color: colorless, water white,

liquid, viscous, liquid, molten light amber, amber

3

Density, kg/m : 950 to 1140 Color, Gardner scale: 3-20 (1:1 toluene)

o

o

o

Cloud point, DACP, C: 10-69 Cloud point, MMAP, C: 23-94 Cloud point, ODM, C: 35-95

o

o

Vapor pressure, kPa: <0.00013 Softening, C: 85-141 T , C: 39-84

g

o

o

Viscosity at 160 C, mPas: Volatility, %: <0.1 to 5 (24H at 180 C)

400-100000

HEALTH & SAFETY

o

Flash point, C: 171-290 Rat oral LD50, mg/kg: >2000 to >5000

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

UN/NA class: 3257

ECOLOGICAL PROPERTIES

Biodegradation probability: 12.7%/28d//not readily biodegradable

USE & PERFORMANCE

Outstanding properties: Provides very light color, along with excellent oxidative stability. Color

stability and excellent peel and tack properties. Low odor and volatility. Improved strength and

water resistance. Heat resistance, and wide compatibility and solubility. Excellent balance of tack

and adhesive and cohesive properties. Excellent balance of shear strength and adhesive and cohe-

sive properties. Tack retention. UV stability. Excellent resistance to acids, alkalis, and moisture.

Recommended for polymers: styrene phase of SBCs, EVAs blended with other rosin esters or AMS

phenolics, paraffin, microcrystalline, FT and PE wax, natural and synthetic rubbers, low vinyl-ace-

tate concentration EVA copolymers, SIS block copolymers, amorphous poly-alpha olefins, paraf-

fin, microcrystalline waxes, amorphous PP, SBS, APO rubber, terpene resins, rosin and modified

rosins, rosin esters, paraffin and microcrystalline waxes, coumarone-indene resins, linseed, soy-

bean and mineral oils, the polystyrene portions of styrenic block copolymers, acrylic, polyester,

epoxy resins, and chlorinated rubber, medium and long drying oils. Not compatible with all grades

of these polymers at all ratios.

Recommended for products: adhesives for packaging, bookbinding, nonwovens, and assembly

applications, woodworking, PSAs for tapes and labels, building and construction, automotive

refinish, laminating, sealants, caulks, footwear and leather, graphic arts, printing inks, paint and

varnish, lithographic (cold set) inks, and concrete curing compounds