Page 93 - Handbook of Surface Improvement and Modification

P. 93

88 Tackifiers

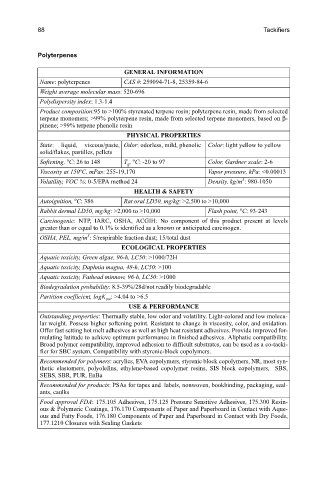

Polyterpenes

GENERAL INFORMATION

Name: polyterpenes CAS #: 259094-71-8, 25359-84-6

Weight average molecular mass: 520-696

Polydispersity index: 1.3-1.4

Product composition:95 to >100% styrenated terpene rosin; polyterpene resin, made from selected

terpene monomers; >99% polyterpene resin, made from selected terpene monomers, based on β-

pinene; >99% terpene phenolic resin

PHYSICAL PROPERTIES

State: liquid, viscous/paste, Odor: odorless, mild, phenolic Color: light yellow to yellow

solid/flakes, pastilles, pellets

o

o

Softening, C: 26 to 148 T , C: -20 to 97 Color, Gardner scale: 2-6

g

o

Viscosity at 150 C, mPas: 255-19,170 Vapor pressure, kPa: <0.00013

3

Volatility, VOC %: 0-5/EPA method 24 Density, kg/m : 980-1050

HEALTH & SAFETY

o

Autoignition, C: 386 Rat oral LD50, mg/kg: >2,500 to >10,000

o

Rabbit dermal LD50, mg/kg: >2,000 to >10,000 Flash point, C: 93-243

Carcinogenic: NTP, IARC, OSHA, ACGIH: No component of this product present at levels

greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

3

OSHA, PEL, mg/m : 5/respirable fraction dust; 15/total dust

ECOLOGICAL PROPERTIES

Aquatic toxicity, Green algae, 96-h, LC50: >1000/72H

Aquatic toxicity, Daphnia magna, 48-h, LC50: >100

Aquatic toxicity, Fathead minnow, 96-h, LC50: >1000

Biodegradation probability: 8.5-39%/28d/not readily biodegradable

Partition coefficient, logK : >4.04 to >6.5

ow

USE & PERFORMANCE

Outstanding properties: Thermally stable, low odor and volatility. Light-colored and low molecu-

lar weight. Possess higher softening point. Resistant to change in viscosity, color, and oxidation.

Offer fast setting hot melt adhesives as well as high heat resistant adhesives. Provide improved for-

mulating latitude to achieve optimum performance in finished adhesives. Aliphatic compatibility.

Broad polymer compatibility, improved adhesion to difficult substrates, can be used as a co-tacki-

fier for SBC system. Compatibility with styrenic-block copolymers.

Recommended for polymers: acrylics, EVA copolymers, styrenic block copolymers, NR, most syn-

thetic elastomers, polyolefins, ethylene-based copolymer resins, SIS block copolymers, SBS,

SEBS, SBR, PUR, EnBa

Recommended for products: PSAs for tapes and labels, nonwoven, bookbinding, packaging, seal-

ants, caulks

Food approval FDA: 175.105 Adhesives, 175.125 Pressure Sensitive Adhesives, 175.300 Resin-

ous & Polymeric Coatings, 176.170 Components of Paper and Paperboard in Contact with Aque-

ous and Fatty Foods, 176.180 Components of Paper and Paperboard in Contact with Dry Foods,

177.1210 Closures with Sealing Gaskets