Page 90 - Handbook of Surface Improvement and Modification

P. 90

6.2 Additives used 85

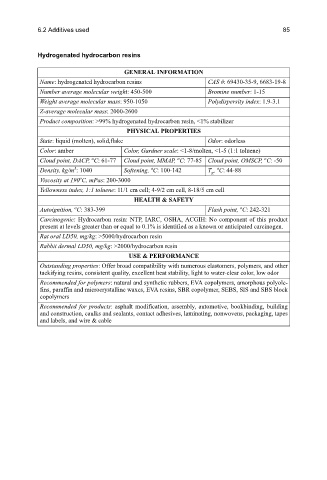

Hydrogenated hydrocarbon resins

GENERAL INFORMATION

Name: hydrogenated hydrocarbon resins CAS #: 69430-35-9, 6683-19-8

Number average molecular weight: 450-500 Bromine number: 1-15

Weight average molecular mass: 950-1050 Polydispersity index: 1.9-3.1

Z-average molecular mass: 2000-2600

Product composition: >99% hydrogenated hydrocarbon resin, <1% stabilizer

PHYSICAL PROPERTIES

State: liquid (molten), solid,flake Odor: odorless

Color: amber Color, Gardner scale: <1-8/molten, <1-5 (1:1 toluene)

o

o

o

Cloud point, DACP, C: 61-77 Cloud point, MMAP, C: 77-85 Cloud point, OMSCP, C: -50

o

o

3

Density, kg/m : 1040 Softening, C: 100-142 T , C: 44-88

g

o

Viscosity at 190 C, mPas: 200-3000

Yellowness index, 1:1 toluene: 11/1 cm cell; 4-9/2 cm cell, 8-18/5 cm cell

HEALTH & SAFETY

o

o

Autoignition, C: 383-399 Flash point, C: 242-321

Carcinogenic: Hydrocarbon resin: NTP, IARC, OSHA, ACGIH: No component of this product

present at levels greater than or equal to 0.1% is identified as a known or anticipated carcinogen.

Rat oral LD50, mg/kg: >5000/hydrocarbon resin

Rabbit dermal LD50, mg/kg: >2000/hydrocarbon resin

USE & PERFORMANCE

Outstanding properties: Offer broad compatibility with numerous elastomers, polymers, and other

tackifying resins, consistent quality, excellent heat stability, light to water-clear color, low odor

Recommended for polymers: natural and synthetic rubbers, EVA copolymers, amorphous polyole-

fins, paraffin and microcrystalline waxes, EVA resins, SBR copolymer, SEBS, SIS and SBS block

copolymers

Recommended for products: asphalt modification, assembly, automotive, bookbinding, building

and construction, caulks and sealants, contact adhesives, laminating, nonwovens, packaging, tapes

and labels, and wire & cable