Page 247 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 247

224 High Temperaturr Solid Oxide Fuel Cells: Fundamentals, Drsign and Applications

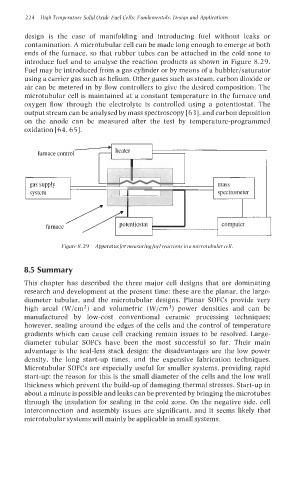

design is the ease of manifolding and introducing fuel without leaks or

contamination. A microtubular cell can be made long enough to emerge at both

ends of the furnace, so that rubber tubes can be attached in the cold zone to

introduce fuel and to analyse the reaction products as shown in Figure 8.29.

Fuel may be introduced from a gas cylinder or by means of a bubbler/saturator

using a carrier gas such as helium. Other gases such as steam, carbon dioxide or

air can be metered in by flow controllers to give the desired composition. The

microtubular cell is maintained at a constant temperature in the furnace and

oxygen flow through the electrolyte is controlled using a potentiostat. The

output stream can be analysed by mass spectroscopy [63], and carbon deposition

on the anode can be measured after the test by temperature-programmed

oxidation [64,65].

Figure 8.29 Apparatus for measuringjuel reactions ina microtubularcell.

8.5 Summary

This chapter has described the three major cell designs that are dominating

research and development at the present time: these are the planar, the large-

diameter tubular, and the microtubular designs. Planar SOFCs provide very

high areal (W/cm2) and volumetric (W/cm3) power densities and can be

manufactured by low-cost conventional ceramic processing techniques;

however, sealing around the edges of the cells and the control of temperature

gradients which can cause cell cracking remain issues to be resolved. Large-

diameter tubular SOFCs have been the most successful so far. Their main

advantage is the seal-less stack design; the disadvantages are the low power

density, the long start-up times, and the expensive fabrication techniques.

Microtubular SOFCs are especially useful for smaller systems, providing rapid

start-up; the reason for this is the small diameter of the cells and the low wall

thickness which prevent the build-up of damaging thermal stresses. Start-up in

about a minute is possible and leaks can be prevented by bringing the microtubes

through the insulation for sealing in the cold zone. On the negative side, cell

interconnection and assembly issues are significant, and it seems likely that

microtubular systems will mainly be applicable in small systems.