Page 246 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 246

Cell and Stack Designs 223

I\ air inlet insula 'on

\

I

igaiti heat exchanger

I

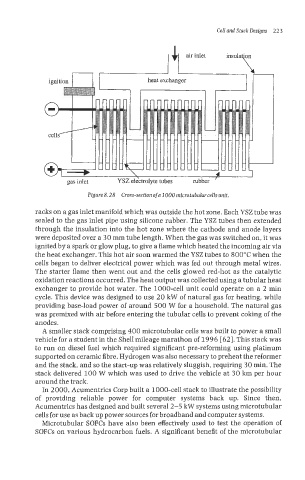

Figure 8.28 Cross-section of n 1000 rnicrotubularcells unit.

racks on a gas inlet manifold which was outside the hot zone. Each YSZ tube was

sealed to the gas inlet pipe using silicone rubber. The YSZ tubes then extended

through the insulation into the hot zone where the cathode and anode layers

were deposited over a 30 mm tube length. When the gas was switched on, it was

ignited by a spark or glow plug, to give a flame which heated the incoming air via

the heat exchanger. This hot air soon warmed the YSZ tubes to 800°C when the

cells began to deliver electrical power which was fed out through metal wires.

The starter flame then went out and the cells glowed red-hot as the catalytic

oxidation reactions occurred. The heat output was collected using a tubular heat

exchanger to provide hot water. The 1000-cell unit could operate on a 2 min

cycle. This device was designed to use 20 ItW of natural gas for heating, while

providing base-load power of around 500 W for a household. The natural gas

was premixed with air before entering the tubular cells to prevent coking of the

anodes.

A smaller stack comprising 400 microtubular cells was built to power a small

vehicle for a student in the Shell mileage marathon of 1996 [62]. This stack was

to run on diesel fuel which required significant pre-reforming using platinum

supported on ceramic fibre. Hydrogen was also necessary to preheat the reformer

and the stack, and so the start-up was relatively sluggish, requiring 30 min. The

stack delivered 100 W which was used to drive the vehicle at 30 km per hour

around the track.

In 2000, Acumentrics Corp buiIt a 1000-cell stack to illustrate the possibility

of providing reliable power for computer systems back up. Since then,

Acumentrics has designed and built several 2-5 kW systems using microtubular

cells for use as back up power sources for broadband and computer systems.

Microtubular SOFCs have also been effectively used to test the operation of

SOFCs on various hydrocarbon fuels. A significant benefit of the microtubular