Page 242 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 242

Cell and Stack Designs 2 19

of the cells compared to the tubular SOFC. When fully optimised with respect to

the number of ribs and the resulting performance, such HPD-SOFCs are expected

to be initially used in 5 kW residential power systems mentioned in Chapter 13.

8.4 Microtubular SOFC Design

The earliest reports of work on microtubular SOFCs were in the early 1990s

when the possibility of extruding thin-walled YSZ electrolyte tubes, 1-5 mm in

diameter and between 100 and 200 pm wall thickness, was demonstrated [38],

and the ionic conductivity and leak tightness of such electrolyte tubes were

found to be good [39, 401. There are two major benefits of microtubular SOFCs.

The first is the increase in volumetric power density when compared with the

large-diameter tubular designs discussed in Section 8.3. Power density scales

with the reciprocal of tube diameter. Therefore a 2 mm diameter microtubular

SOFC could provide ten times more power per stack volume than a 20 mm

diameter tubular cell. Another order of magnitude increase could be achieved by

going to 0.2 mm diameter tubes, but this is difficult because the connections are

then more numerous and problematic to apply. The most significant issue in

microtubular cells is applying the electrode and connecting the metal contact

inside the bore of a very small-diameter tube.

The second major benefit of the microtubular design is a high thermal shock

resistance [41]. Whereas the large-diameter tubular SOFCs are prone to cracking

if they are rapidly heated, the microtubular SOFCs do not crack even when

heated in a blow torch to their operating temperature of about 850°C in as little

as 5 s. This is a marked advantage in applications where start-up time is critical.

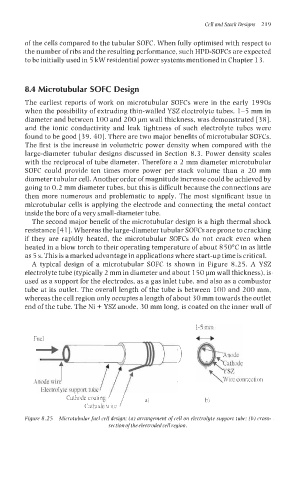

A typical design of a microtubular SOFC is shown in Figure 8.25. A YSZ

electrolyte tube (typically 2 mm in diameter and about 150 pm wall thickness), is

used as a support for the electrodes, as a gas inlet tube, and also as a combustor

tube at its outlet. The overall length of the tube is between 100 and 200 mm,

whereas the cell region only occupies a length of about 30 mm towards the outlet

end of the tube. The Ni + YSZ anode, 30 mm long, is coated on the inner wall of

1-5 mm

Fuel

Electrolyte support tube

Cathode coating b)

Cathode wire

Figure 8.25 Microtubular fuel cell design: (a) arrangement of cell on electrolyte support tube: (b) cross-

section ofthe electroded cell region.