Page 240 - High Temperature Solid Oxide Fuel Cells Fundamentals, Design and Applications

P. 240

Cell and Stack Designs 2 1 7

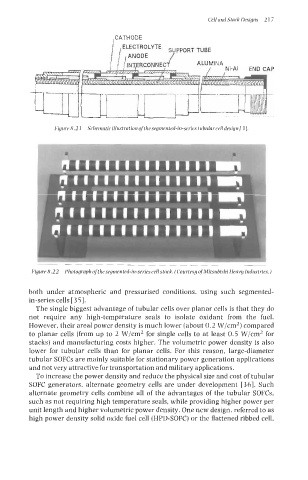

Figure 8.21 Schematic illustration of thesegmented-in-series tubularcelldesignl31.

Figure 8.22 Photograph ofthesegrnented-in-series cell stack. (Courtesy of Mitsubishi Heavy Industries.)

both under atmospheric and pressurised conditions, using such segmented-

in-series cells [ 3 51.

The single biggest advantage of tubular cells over planar cells is that they do

not require any high-temperature seals to isolate oxidant from the fuel.

However, their areal power density is much lower (about 0.2 W/cm2) compared

to planar cells (from up to 2 W/cm2 for single cells to at least 0.5 W/cm2 for

stacks) and manufacturing costs higher. The volumetric power density is also

lower for tubular cells than for planar cells. For this reason, large-diameter

tubular SOFCs are mainly suitable for stationary power generation applications

and not very attractive for transportation and military applications.

To increase the power density and reduce the physical size and cost of tubular

SOFC generators, alternate geometry cells are under development [ 3 61. Such

alternate geometry cells combine all of the advantages of the tubular SOFCs,

such as not requiring high temperature seals, while providing higher power per

unit length and higher volumetric power density. One new design, referred to as

high power density solid oxide fuel cell (HPD-SOFC) or the flattened ribbed cell,