Page 262 - How To Implement Lean Manufacturing

P. 262

240 Cha pte r S i x tee n

The OEE Initiative

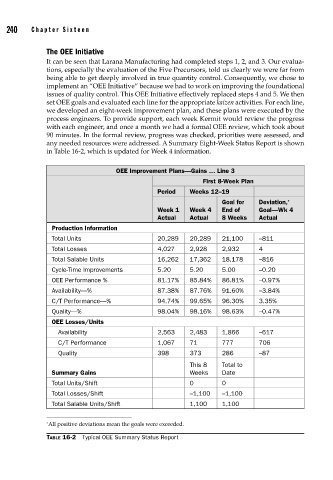

It can be seen that Larana Manufacturing had completed steps 1, 2, and 3. Our evalua-

tions, especially the evaluation of the Five Precursors, told us clearly we were far from

being able to get deeply involved in true quantity control. Consequently, we chose to

implement an “OEE Initiative” because we had to work on improving the foundational

issues of quality control. This OEE Initiative effectively replaced steps 4 and 5. We then

set OEE goals and evaluated each line for the appropriate kaizen activities. For each line,

we developed an eight-week improvement plan, and these plans were executed by the

process engineers. To provide support, each week Kermit would review the progress

with each engineer, and once a month we had a formal OEE review, which took about

90 minutes. In the formal review, progress was checked, priorities were assessed, and

any needed resources were addressed. A Summary Eight-Week Status Report is shown

in Table 16-2, which is updated for Week 4 information.

OEE Improvement Plans—Gains … Line 3

First 8-Week Plan

Period Weeks 12–19

Goal for Deviation, *

Week 1 Week 4 End of Goal—Wk 4

Actual Actual 8 Weeks Actual

Production Information

Total Units 20,289 20,289 21,100 –811

Total Losses 4,027 2,928 2,932 4

Total Salable Units 16,262 17,362 18,178 –816

Cycle-Time Improvements 5.20 5.20 5.00 –0.20

OEE Performance % 81.17% 85.84% 86.81% –0.97%

Availability—% 87.38% 87.76% 91.60% –3.84%

C/T Performance—% 94.74% 99.65% 96.30% 3.35%

Quality—% 98.04% 98.16% 98.63% –0.47%

OEE Losses/Units

Availability 2,563 2,483 1,866 –617

C/T Performance 1,067 71 777 706

Quality 398 373 286 –87

This 8 Total to

Summary Gains Weeks Date

Total Units/Shift 0 0

Total Losses/Shift –1,100 –1,100

Total Salable Units/Shift 1,100 1,100

∗ All positive deviations mean the goals were exceeded.

TABLE 16-2 Typical OEE Summary Status Report