Page 402 - Hydrocarbon Exploration and Production Second Edition

P. 402

Managing the Producing Field 389

total flowrate fluid density

caliper

gradio-

Layer A

manometer

B

C spinner

D

oil

density

depth

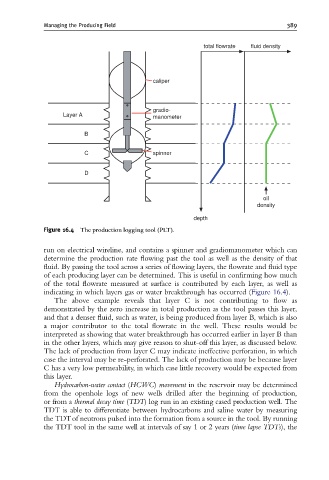

Figure 16.4 The production logging tool (PLT).

run on electrical wireline, and contains a spinner and gradiomanometer which can

determine the production rate flowing past the tool as well as the density of that

fluid. By passing the tool across a series of flowing layers, the flowrate and fluid type

of each producing layer can be determined. This is useful in confirming how much

of the total flowrate measured at surface is contributed by each layer, as well as

indicating in which layers gas or water breakthrough has occurred (Figure 16.4).

The above example reveals that layer C is not contributing to flow as

demonstrated by the zero increase in total production as the tool passes this layer,

and that a denser fluid, such as water, is being produced from layer B, which is also

a major contributor to the total flowrate in the well. These results would be

interpreted as showing that water breakthrough has occurred earlier in layer B than

in the other layers, which may give reason to shut-off this layer, as discussed below.

The lack of production from layer C may indicate ineffective perforation, in which

case the interval may be re-perforated. The lack of production may be because layer

C has a very low permeability, in which case little recovery would be expected from

this layer.

Hydrocarbon-water contact (HCWC) movement in the reservoir may be determined

from the openhole logs of new wells drilled after the beginning of production,

or from a thermal decay time (TDT) log run in an existing cased production well. The

TDT is able to differentiate between hydrocarbons and saline water by measuring

the TDTof neutrons pulsed into the formation from a source in the tool. By running

the TDT tool in the same well at intervals of say 1 or 2 years (time lapse TDTs), the