Page 128 - Improving Machinery Reliability

P. 128

100 Improving Machinery Reliability

rijiiiii

STAGE NO. I

a 0 I

-€-

OUTBOARD IYPELL INBOARD

BEARING I I BEARING

twEkn I IuPLEn I

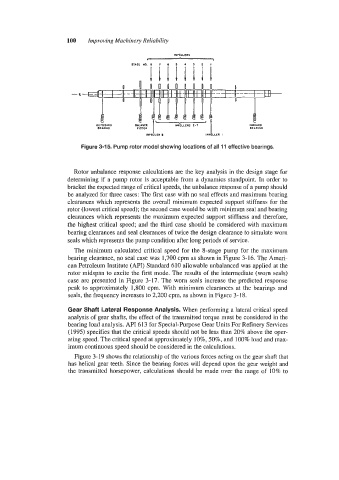

Figure 3-15. Pump rotor model showing locations of all 11 effective bearings.

Rotor unbalance response calculations are the key analysis in the design stage for

determining if a pump rotor is acceptable from a dynamics standpoint. In order to

bracket the expected range of critical speeds, the unbalance response of a pump should

be analyzed for three cases: The first case with no seal effects and maximum bearing

clearances which represents the overall minimum expected support stiffness for the

rotor (lowest critical speed); the second case would be with minimum seal and bearing

clearances which represents the maximum expected support stiffness and therefore,

the highest critical speed; and the third case should be considered with maximum

bearing clearances and seal clearances of twice the design clearance to simulate worn

seals which represents the pump condition after long periods of service.

The minimum calculated critical speed for the 8-stage pump for the maximum

bearing clearance, no seal case was 1,700 cpm as shown in Figure 3-16. The Ameri-

can Petroleum Institute (API) Standard 610 allowable unbalanced was applied at the

rotor midspan to excite the first mode. The results of the intermediate (worn seals)

case are presented in Figure 3-17. The worn seals increase the predicted response

peak to approximately 1,800 cpm. With minimum clearances at the bearings and

seals, the frequency increases to 2,200 cpm, as shown in Figure 3- 18.

Gear Shaft Lateral Response Analysis. When performing a lateral critical speed

analysis of gear shafts, the effect of the transmitted torque must be considered in the

bearing load analysis. API 61 3 for Special-Purpose Gear Units For Refinery Services

(1995) specifies that the critical speeds should not be less than 20% above the oper-

ating speed. The critical speed at approximately IO%, 50%, and 100% load and max-

imum continuous speed should be considered in the calculations.

Figure 3-19 shows the relationship of the various forces acting on the gear shaft that

has helical gear teeth. Since the bearing forces will depend upon the gear weight and

the transmitted horsepower, calculations should be made over the range of 10% to