Page 251 - Improving Machinery Reliability

P. 251

222 Improving Machinery Reliability

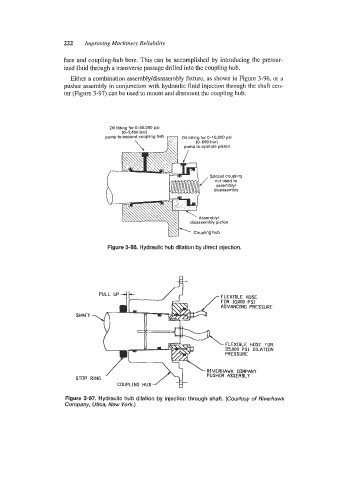

face and coupling-hub bore. This can be accomplished by introducing the pressur-

ized fluid through a transverse passage drilled into the coupling hub.

Either a combination assembly/disassembly fixture, as shown in Figure 3-96, or a

pusher assembly in conjunction with hydraulic fluid injection through the shaft cen-

ter (Figure 3-97) can be used to mount and dismount the coupling hub.

Oil fitting for 0-50,000 psi

(0-3,450 bar)

Oil fitting for 0-10,000 psi

pump to operate piston

, Special coupling

nut used lo

assembly/

disassembly

Figure 3-96. Hydraulic hub dilation by direct injection.

FLEXIBLE HOSE

FOR 10,000 PSI

ADVANCING PRESSURE

FLEXIBLE HOSE FOR

35,000 PSI DILATION

PRESSURE

RIVERHAWK COMPANY

PUSHER ASSEMBLY

Figure 3-97. Hydraulic hub dilation by injection through shaft. (Courtesy of Riverhawk

Company, Utica, New York.)