Page 248 - Improving Machinery Reliability

P. 248

Muchinery Reliability Audits and Reviews 219

required interference of 0.0015 inch per inch of shaft diameter. While the solid line

in Figure 3-91 would now tell us that the hub could expand this required amount by

heating it to a temperature 238°F above ambient, we may actually want to facilitate

the hub attachment operation by expanding it another 2 mils, or alternatively, say

0.002 inch. Thus the hub should expand 0.008 mil on a 4-inch shaft, or 2 mils per

inch of diameter. We would therefore, choose to enter the abscissa of Figure 3-91 at

2.0 mildinch and find that the hub should be heated io a temperature 318°F above

ambient. The same result can be obtained by entering the abscissa at 1.5 mils/inch

and reading off the AT value at the dotted-line intersection.

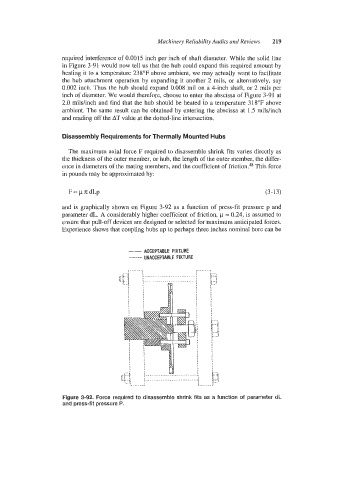

Disassembly Requirements for Thermally Mounted Hubs

The maximum axial force F required to disassemble shrink fits varies directly as

the thickness of the outer member, or hub, the length of the outer member, the differ-

ence in diameters of the mating members, and the coefficient of frictions4* This force

in pounds may be approximated by:

F = p x dLp (3-13)

and is graphically shown on Figure 3-92 as a function of press-fit pressure p and

parameter d&. A considerably higher coefficient of friction, p = 0.24, is assumed to

ensure that pull-off devices are designed or selected for maximum anticipated forces.

E.xperience shows that coupling hubs up to perhaps three inches nominal bore can be

- ACCEPTABLE FIXTURE

UNACCEPTABLE FIXTURE

r.. ..... ,

! : I

.__.I

I ....... _. ..... ....

Figure 3-92. Force required to disassemble shrink fits as a function of parameter dL

and press-fit pressure P.