Page 262 - Improving Machinery Reliability

P. 262

Machinery Reliability Audits and Reviews 233

Typical audit interview questions. (Continued)

What major problems have occurred in recent years?

How is machinery monitored?

-Operations

-Technical

-Maintenance

Are data collected for long-term records and future reference?

-.Data distribution routine: How done, where sent?

Do you have a means of rapidly relating operational problems with their impact on

process machinery? If so, how is it done?

What would you like to see implemented in order to improve the reliability of the

dant?

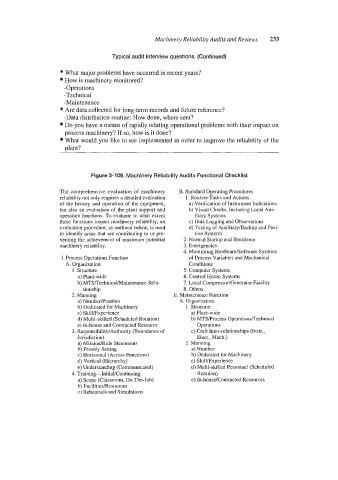

Figure 3-106. Machinery Reliability Audits Functional Checklist

The comprehensive evaluation of machinery B. Standard Operating Procedures

reliability not only requires a detailed evaluation I. Routine Tasks and Actions

of the history and operation of the equipment, a) Verification of Instrument Indications

but also an evaluation of the plant support and b) Visual Checks, Including Local Aux-

operation functions. To evaluate to what extent iliary Systems

these functions impact machinery reliability, an c) Data Logging and Observations

evaluation procedure, as outlined below, is used d) Testing of Auxiliary/Backup and Posi-

to identify areas that are contributing to or pre- tive Systems

venting the achievement of maximum potential 2. Normal Startup and Shutdown

machinery reliability. 3. Emergencies

4. Monitoring Hardwardsoftware Systems

1. Process Operations Function of Process Variables and Mechanical

A. Organization Conditions

1. Structure 5. Computer Systems

a) Plant-wide 6. Control House Systems

b) MTS/Technical/Maintenance Rela- 7. Local CompressorlGenerator Facility

tionship 8. Others

2. Manning 11. Maintenance Function

a) NuinbedPosition A. Organization

b) Dedicated for Machinery 1. Structure

c) SkilVExperience a) Plant-wide

d) Multi-skilled (Scheduled Rotation) b) MTSlProcess OperationsRechnical

e) In-house and Contracted Resource Operations

3. ResponsibilitylAuthority (Boundaries of c) Craft Inter-relationships (Instr.,

Jurisdiction) Elect., Mach.)

a) MissiodRole Statements 2. Manning

b) Priority Setting a) Number

c) Horizontal (Across Functions) b) Dedicated for Machinery

d) Vertical (Hierarchy) c) SkilllExperience

e) Understanding (Communicated) d) Multi-skilled Personnel (Scheduled

4. Training-InitiallContinuing Rotation)

a) Scope (Classroom, On-The-Job) e) In-houselContracted Resources

b) FacilitiesResources

c) Rehearsals and Simulations