Page 104 - Industrial Power Engineering and Applications Handbook

P. 104

m

- -

In

- Starting and control of slip-ring induction motors 5/85

I I I 1

Star connected rotor 1 Star connected rotor J

' Brushes

Star connected resistance

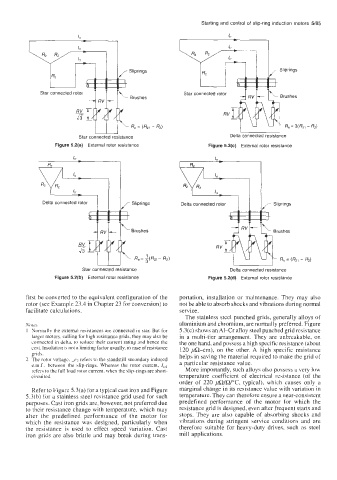

Figure 5.2(a) External rotor resistance

-

17, -

-

-

I,, -

& ( I /-

Delta connected rotor Delta connected rotor

I

Sliprings

Star connected resistance Delta connected resistance

Figure 5.2(b) External rotor resistance Figure 5.2(d) External rotor resistance

first be converted to the equivalent configuration of the portation, installation or maintenance. They may also

rotor (see Example 23.4 in Chapter 23 for conversion) to not be able to absorb shocks and vibrations during normal

facilitate calculations. service.

The stainless steel punched grids, generally alloys of

Notes aluminium and chromium, are normally preferred. Figure

I Normally the external resistances are connected in star. But for 5.3(c) shows an A1-Cr alloy steel punched grid resistance

larger motors, calling for high resistance grids, they may also be in a multi-tier arrangement. They are unbreakable, on

connected in delta, to reduce their current rating and hence the the one hand, and possess a high specific resistance (about

cost. Insulation is not a limiting factor usually, in case of resistance 120 $2-cm), on the other. A high specific resistance

grids. helps in saving the material required to make the grid of

Z The rotor voltage, \,e2 refers to the standstill secondary induced a particular resistance value.

e.m.f.. between the slip-rings. Whereas the rotor current, I,,

refers to the full load rotor current, when the slip-rings are short- More importantly, such alloys also possess a very low

circuited. temperature coefficient of electrical resistance (of the

order of 220 pQIQ/"C, typical), which causes only a

Refer to Figure 5.3(a) for a typical cast iron and Figure marginal change in its resistance value with variation in

5.3(b) for a stainless steel resistance grid used for such temperature. They can therefore ensure a near-consistent

purposes. Cast iron grids are, however, not preferred due predefined performance of the motor for which the

to their resistance change with temperature, which may resistance grid is designed, even after frequent starts and

alter the predefined performance of the motor for stops. They are also capable of absorbing shocks and

which the resistance was designed, particularly when vibrations during stringent service conditions and are

the resistance is used to effect speed variation. Cast therefore suitable for heavy-duty drives, such as steel

iron grids are also brittle and may break during trans- mill applications.