Page 193 - Industrial Power Engineering and Applications Handbook

P. 193

Special-purpose motors 71 173

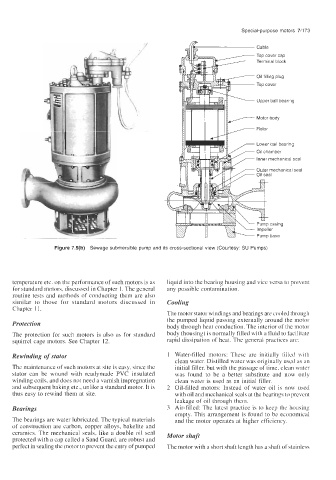

Terminal block

Upper ball bearing

Lower ball bearing

Inner mechanical seal

Figure 7.5(b) Sewage submersible pump and its cross-sectional view (Courtesy: SU Pumps)

temperature etc. on the performance of such motors is as liquid into the bearing housing and vice versa to prevent

for standard motors, discussed in Chapter 1. The general any possible contamination.

routine tests and methods of conducting them are also

similar to those for standard motors discussed in Cooling

Chapter 11.

The motor stator windings and bearings are cooled through

the pumped liquid passing externally around the motor

Protection body through heat conduction. The interior of the motor

The protection for such motors is also as for standard body (housing) is normally filled with a fluid to facilitate

squirrel cage motors. See Chapter 12. rapid dissipation of heat. The general practices are:

Rewinding of stator 1 Water-filled motors: These are initially filled with

clean water. Distilled water was originally used as an

The maintenance of such motors at site is easy, since the initial filler, but with the passage of time, clean water

stator can be wound with readymade PVC insulated was found to be a better substitute and now only

winding coils, and does not need a varnish impregnation clean water is used as an initial filler.

and subsequent baking etc., unlike a standard motor. It is 2 Oil-filled motors: Instead of water oil is now used

thus easy to rewind them at site. with oil and mechanical seals at the bearings to prevent

leakage of oil through them.

Bearings 3 Air-filled: The latest practice is to keep the housing

empty. This arrangement is found to be economical

The bearings are water lubricated. The typical materials and the motor operates at higher efficiency.

of construction are carbon, copper alloys, bakelite and

ceramics. The mechanical seals, like a double oil seal Motor shaft

protected with a cap called a Sand Guard, are robust and

perfect in sealing the motor to prevent the entry of pumped The motor with a short shaft length has a shaft of stainless