Page 202 - Industrial Power Engineering and Applications Handbook

P. 202

7/182 Industrial Power Engineering and Applications Handbook

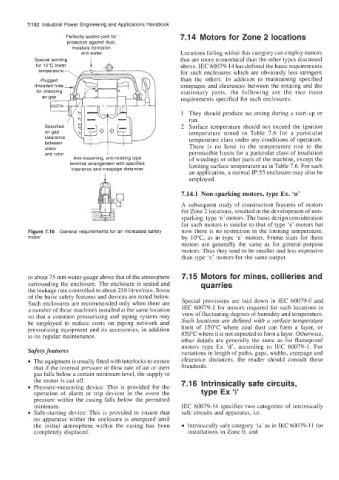

Perfectly sealed joint for 7.14 Motors for Zone 2 locations

protection against dust,

moisture corrosion

and water Locations falling within this category can employ motors

Special winding that are more economical than the other types discussed

for 10°C lower above. IEC 60079-14 has defined the basic requirements

for such enclosures which are obviously less stringent

than the others. In addition to maintaining specified

creepages and clearances between the rotating and the

stationary parts, the following are the two main

requirements specified for such enclosures:

1 They should produce no arcing during a start-up or

run.

2 Surface temperature should not exceed the ignition

temperature noted in Table 7.6 for a particular

temperature class under any conditions of operation.

There is no limit to the temperature rise to the

and rotor permissible limits for a particular class of insulation

Anti-loosening, anti-rotating type of windings or other parts of the machine, except the

terminal arrangement with specified limiting surface temperature as in Table 7.6. For such

clearance and creepage distances

an application, a normal 1P:SS enclosure may also be

employed.

7.14.1 Non-sparking motors, type Ex. ‘n’

A subsequent study of construction features of motors

for Zone 2 locations, resulted in the development of non-

sparking, type ‘n’ motors. The basic design consideration

for such motors is similar to that of type ‘e’ motors but

Figure 7.16 General requirements for an increased safety now there is no restriction in the limiting temperature,

motor by 10”C, as in type ‘e’ motors. Frame sizes for these

motors are generally the same as for general-purpose

motors. Thus they tend to be smaller and less expensive

than type ‘e’ motors for the same output.

to about 75 mm water-gauge above that of the atmosphere 7.15 Motors for mines, collieries and

surrounding the enclosure. The enclosure is sealed and quarries

the leakage rate controlled to about 250 litredmin. Some

of the basic safety features and devices are noted below.

Such enclosures are recommended only when there are Special provisions are laid down in IEC 60079-0 and

a number of these machines installed at the same location IEC 60079-1 for motors required for such locations in

so that a common pressurizing and piping system may view of fluctuating degrees of humidity and temperature.

be employed to reduce costs on piping network and Such locations are defined with a surface temperature

pressurizing equipment and its accessories, in addition limit of 150°C where coal dust can form a layer, or

to its regular maintenance. 450°C where it is not expected to form a layer. Otherwise,

other details are generally the samc as for flameproof

motors type Ex ‘d’, according to IEC 60079-1. For

Safety features variations in length of paths, gaps, widths, creepage and

The equipment is usually fitted with interlocks to ensure clearance distances, the reader should consult these

that if the internal pressure or flow rate of air or inert Standards.

gas falls below a certain minimum level, the supply to

the motor is cut off. 7.1 6 Intrinsically safe circuits,

Pressure-measuring device: This is provided for the

operation of alarm or trip devices in the event the type Ex ‘i’

pressure within the casing falls below the permitted

minimum. IEC 60079-14 specifies two categories of intrinsically

Safe-starting device: This is provided to ensure that safe circuits and apparatus, i.e.

no apparatus within the enclosure is energized until

the initial atmosphere within the casing has been 0 Intrinsically safe category ‘ia’ as in IEC 60079-1 1 for

completely displaced. installations in Zone 0, and