Page 254 - Industrial Power Engineering and Applications Handbook

P. 254

Installation and maintenance of electric motors 10/233

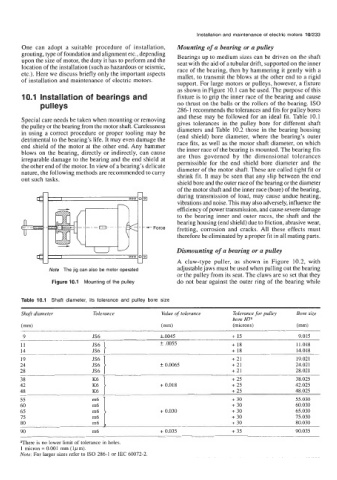

One can adopt a suitable procedure of installation, Mounting of a bearing or a pulley

grouting, type of foundation and alignment etc., depending Bearings up to medium sizes can be driven on the shaft

upon the size of motor, the duty it has to perform and the seat with the aid of a tubular drift, supported on the inner

location of the installation (such as hazardous or seismic, race of the bearing, then by hammering it gently with a

etc.). Here we discuss briefly only the important aspects mallet, to transmit the blows at the other end to a rigid

of installation and maintenance of electric motors.

support. For large motors or pulleys, however, a fixture

as shown in Figure 10.1 can be used. The purpose of this

10.1 Installation of bearings and fixture is to grip the inner race of the bearing and cause

pu I ley s no thrust on the balls or the rollers of the bearing. IS0

286-1 recommends the tolerances and fits for pulley bores

and these may be followed for an ideal fit. Table 10.1

Special care needs be taken when mounting or removing gives tolerances in the pulley bore for different shaft

the pulley or the bearing from the motor shaft. Carelessness diameters and Table 10.2 those in the bearing housing

in using a correct procedure or proper tooling may be (end shield) bore diameter, where the bearing’s outer

detrimental to the bearing’s life. It may even damage the race fits, as well as the motor shaft diameter, on which

end shield of the motor at the other end. Any hammer the inner race of the bearing is mounted. The bearing fits

blows on the bearing, directly or indirectly, can cause are thus governed by the dimensional tolerances

irreparable damage to the bearing and the end shield at permissible for the end shield bore diameter and the

the other end of the motor. In view of a bearing’s delicate diameter of the motor shaft. These are called tight fit or

nature, the following methods are recommended to carry shrink fit. It may be seen that any slip between the end

out such tasks.

shield bore and the outer race of the bearing or the diameter

of the motor shaft and the inner race (bore) of the bearing,

during transmission of load, may cause undue heating,

I

vibrations and noise. This may also adversely, influence the

efficiency of power transmission, and cause severe damage

to the bearing inner and outer races, the shaft and the

bearing housing (end shield) due to friction, abrasive wear,

fretting, corrosion and cracks. All these effects must

therefore be eliminated by a proper fit in all mating parts.

Dismounting of a bearing or a pulley

A claw-type puller, as shown in Figure 10.2, with

Note The jig can also be motor operated adjustable jaws must be used when pulling out the bearing

or the pulley from its seat. The claws are so set that they

Figure 10.1 Mounting of the pulley do not bear against the outer ring of the bearing while

Table 10.1 Shaft diameter, its tolerance and pulley bore size

Shaft diameter Tolerance Value of tolerance Tolerance for pulley Bore size

bore

(mm) (mm) (microns) (mm)

9 JS6 LO045 + 15 9.015

11 f .0055 + 18 11.018

14 JS6 + 18 14.018

19 E } + 21 19.021

24 f 0.0065 + 21 24.021

28 JS6 + 21 28.021

38 E } + 25 38.025

42 + 0.018 + 25 42.025

48 K6 + 25 48.025

55 + 30 55.030

60 + 30 60.030

65 + 0.030 + 30 65.030

75 m6 + 30 75.030

80 m6 + 30 80.030

90 m6 + 0.035 + 35 90.035

aThere is no lower limit of tolerance in holes.

1 micron = 0.001 mm (lpm).

Note: For larger sizes refer to IS0 286-1 or IEC 60072-2.