Page 259 - Industrial Power Engineering and Applications Handbook

P. 259

10/238 Industrial Power Engineering and Applications Handbook

Table 10.3 Quantity of grease and regreasing intervals

Bearing bore To be injected after running hours Quantity of grease Quantity of initial

dia. d (mm) (g) grease

(8)

Speed zp.m + 750 1000 1500 3000

45

8000 ~ 8000

50

I

60

65 6o

I

70 40

75 8o

80 100

90

140

95

188

100

80 220

110 260

120

320

130

Courtesy M/s Siemens

motors of 2.4 kV and above. This can be prevented by

grounding one of the bearings to prevent the leakages.

The bearing insulation is thus determined by the

manufacturer while checking the shaft voltage at the

works. This forms a routine in-house test for all HT

and large LT motors.

To detect shaft currents, the normal procedure of

leading manufacturers is to measure the shaft voltage

end to end, with a full voltage applied to the motor

terminals. If this is 300-350 mV or more, it will indicate

that the bearings require insulation, as illustrated in

Figure 10.8. On very large motors, using segmented

punchings, shaft voltages even of the order of 1 to

2 V have been noticed. These voltages are highly

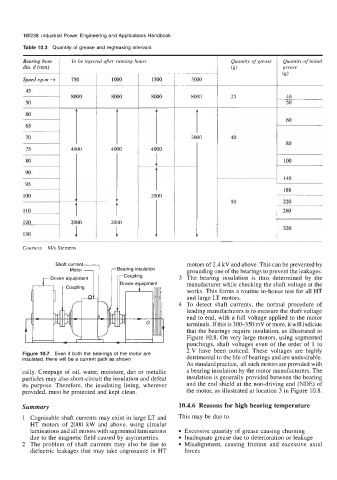

Figure 10.7 Even if both the bearings of the motor are

insulated, there will be a current path as shown detrimental to the life of bearings and are undesirable.

As standard practice, all such motors are provided with

cally. Creepage of oil, water, moisture, dirt or metallic a bearing insulation by the motor manufacturers. The

particles may also short-circuit the insulation and defeat insulation is generally provided between the bearing

its purpose. Therefore, the insulating lining, wherever and the end shield at the non-driving end (NDE) of

provided, must be protected and kept clean. the motor, as illustrated at location 3 in Figure 10.8.

Summary 10.4.6 Reasons for high bearing temperature

1 Cognisable shaft currents may exist in large LT and This may be due to

HT motors of 2000 kW and above, using circular

laminations and all motors with segmented laminations Excessive quantity of grease causing churning

due to the magnetic field caused by asymmetries. Inadequate grease due to deterioration or leakage

2 The problem of shaft currents may also be due to Misalignment, causing friction and excessive axial

dielectric leakages that may take cognisance in HT forces