Page 256 - Industrial Power Engineering and Applications Handbook

P. 256

Installation and maintenance of electric motors 10/235

through cable lugs to ensure a proper grip as shown in - Sprin pressure to be maintained around 150-200

P

Figure 10.4. A poor cable termination will mean arcing g/cm for proper contact of the brushes with the

and localized heat and may lead to joint failure. slip-rings.

For oil-filled control equipment such as autotransformer - Cleanliness of slip-rings and the brushes.

starters or oil circuit breakers (BOCBs or MOCBs, - Slip-rings, if roughened by arcing, must be cleaned

Chapter 19), insulating oil should be checked with fine glass paper, having a similar curvature to

periodically for its insulating properties. Leading the rings using a wooden block on which the glass

manufacturers of this equipment indicate the number paper can be wrapped. Emery cloth should not be

of switching operations under different conditions of used.

load and fault, after which the oil must be replaced - When replacing with the new brushes, the new

and these must be followed. brushes must be first ground to acquire a curvature

Each electric motor and connected control gear is similar to that of the rings.

grounded separately at least two points. The ground - Brush lifting and short-circuiting devices can be

resistance should be checked to ensure continuity of employed for motors required to run continuously

ground conductors. Refer to Chapter 21 for more details for a long period to minimize wear and tear of slip-

on grounding requirements. rings and brushes. However, when speed control is

Insulation resistance of the motor windings between required or switching operations are frequent,

phases and phase to ground should be checked and continuous contact brush gear assembly must be

made up in the event of deficiency, according to Section employed.

9.5.

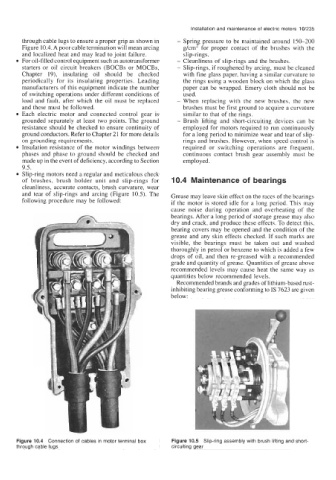

Slip-ring motors need a regular and meticulous check

of brushes, brush holder unit and slip-rings for 10.4 Maintenance of bearings

cleanliness, accurate contacts, brush curvature, wear

and tear of slip-rings and arcing (Figure 10.5). The Grease may leave skin effect on the races of the bearings

following procedure may be followed: if the motor is stored idle for a long period. This may

cause noise during operation and overheating of the

bearings. After a long period of storage grease may also

dry and crack, and produce these effects. To detect this,

bearing covers may be opened and the condition of the

grease and any skin effects checked. If such marks are

visible, the bearings must be taken out and washed

thoroughly in petrol or benzene to which is added a few

drops of oil, and then re-greased with a recommended

grade and quantity of grease. Quantities of grease above

recommended levels may cause heat the same way as

quantities below recommended levels.

Recommended brands and grades of lithium-based rust-

inhibiting bearing grease conforming to IS 7623 are given

below:

Figure 10.4 Connection of cables in motor terminal box Figure 10.5 Slip-ring assembly with brush lifting and short-

through cable lugs circuiting gear