Page 260 - Industrial Power Engineering and Applications Handbook

P. 260

Installation and maintenance of electric motors 10/239

Bearing insulation

Driven equipment

Driven Equipment

earing insulation

Insulation at the foundation

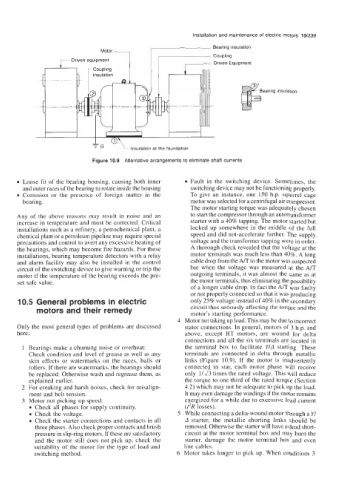

Figure 10.8 Alternative arrangements to eliminate shaft currents

Loose fit of the bearing housing, causing both inner Fault in the switching device. Sometimes, the

and outer races of the bearing to rotate inside the housing switching device may not be functioning properly.

Corrosion or the presence of foreign matter in the To give an instance, one 150 h.p. squirrel cage

bearing. motor was selected for a centrifugal air compressor.

The motor starting torque was adequately chosen

Any of the above reasons may result in noise and an to start the compressor through an autotransformer

increase in temperature and must be corrected. Critical starter with a 40% tapping. The motor started but

installations such as a refinery, a petrochemical plant, a locked up somewhere in the middle of the full

chemical plant or a petroleum pipeline may require special speed and did not-accelerate further. The supply

precautions and control to avert any excessive heating of voltage and the transformer tapping were in order.

the bearings, which may become fire hazards. For these A thorough check revealed that the voltage at the

installations, bearing temperature detectors with a relay motor terminals was much less than 40%. A long

and alarm facility may also be installed in the control cable drop from the A/T to the motor was suspected

circuit of the switching device to give warning or trip the but when the voltage was measured at the A/T

motor if the temperature of the bearing exceeds the pre- outgoing terminals, it was almost the same as at

set safe value. the motor terminals, thus eliminating the possibility

of a longer cable drop. In fact the A/T was faulty

or not properly connected so that it was producing

10.5 General problems in electric only 25% voltage instead of 40% in the secondary

motors and their remedy circuit thus seriously affecting the torque and the

motor’s starting performance.

4 Motor not taking up load. This may be due to incorrect

Only the most general types of problems are discussed stator connections. In general, motors of 3 h.p. and

here: above, except HT motors, are wound for delta

connections and all the six terminals are located in

Bearings make a churning noise or overheat: the terminal box to facilitate YlA starting. These

Check condition and level of grease as well as any terminals are connected in delta through metallic

skin effects or watermarks on the races, balls or links (Figure 10.9). If the motor is inadvertently

rollers. If there are watermarks, the bearings should connected in star, each motor phase will receive

be replaced. Otherwise wash and regrease them, as only 118 times the rated voltage. This will reduce

explained earlier. the torque to one third of the rated torque (Section

For creaking and harsh noises, check for misalign- 4.2) which may not be adequate to pick up the load.

ment and belt tension. It may even damage the windings if the motor remains

Motor not picking up speed: energized for a while due to excessive load current

Check all phases for supply continuity. (Z’R losses).

Check the voltage. While connecting a delta-wound motor through a Yl

Check the starter connections and contacts in all A starter, the metallic shorting links should be

three phases. Also check proper contacts and brush removed. Otherwise the starter will have a dead short-

pressure in slip-ring motors. If these are satisfactory circuit at the motor terminal box and may burn the

and the motor still does not pick up, check the starter, damage the motor terminal box and even

suitability of the motor for the type of load and line cables.

switching method. Motor takes longer to pick up. When conditions 3