Page 288 - Industrial Power Engineering and Applications Handbook

P. 288

Philosophy of quality systems and testing of electrical machines 11/267

~ ~~ ~

Second characteristic Test requirements

number

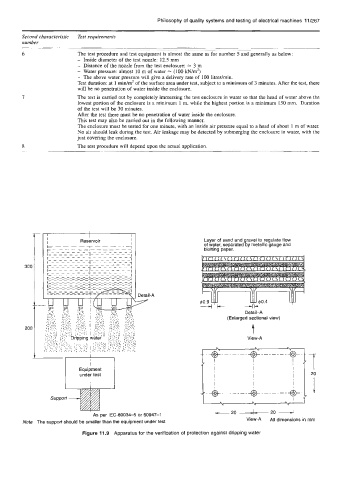

6 The test procedure and test equipment is almost the same as for number 5 and generally as below:

- Inside diameter of the test nozzle: 12.5 mm

- Distance of the nozzle from the test enclosure: = 3 m

- Water pressure: almost 10 m of water (100 kN/m2)

- The above water pressure will give a delivery rate of 100 litredmin.

Test duration: at 1 min/m* of the surface area under test, subject to a minimum of 3 minutes. After the test, there

will be no penetration of water inside the enclosure.

7 The test is carried out by completely immersing the test enclosure in water so that the head of water above the

lowest portion of the enclosure is a minimum 1 m, while the highest portion is a minimum 150 mm. Duration

of the test will be 30 minutes.

After the test there must be no penetration of water inside the enclosure.

This test may also be carried out in the following manner.

The enclosure must be tested for one minute, with an inside air pressure equal to a head of about 1 m of water.

No air should leak during the test. Air leakage may be detected by submerging the enclosure in water, with the

just covering the enclosure.

8 The test procedure will depend upon the actual application.

I

I1 I1

I Reservoir I Layer of sand and gravel to regulate flow

I of water, separated by metallic gauge and

blotting paper.

301

Detail-A

(Enlarged sectional view)

20

support w

Equipment

under test

rn I 'I ! k 3 !

;*

As per IEC-60034-5 or 60947-1 1 2 0 A 2 0 4

Note The support should be smaller than the equipment under test View-A All dimensions in mm

Flgure 11.9 Apparatus for the verification of protection against dripping water