Page 180 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 180

156 Industrial process plant construction estimating and man-hour analysis

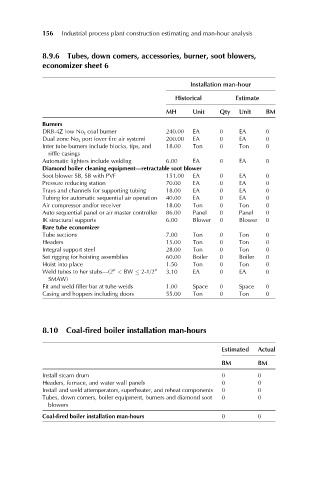

8.9.6 Tubes, down comers, accessories, burner, soot blowers,

economizer sheet 6

Installation man-hour

Historical Estimate

MH Unit Qty Unit BM

Burners

DRB-4Z low Noᵪ coal burner 240.00 EA 0 EA 0

Dual zone Noᵪ port (over fire air system) 200.00 EA 0 EA 0

Inter tube burners include blocks, tips, and 18.00 Ton 0 Ton 0

riffle casings

Automatic lighters include welding 6.00 EA 0 EA 0

Diamond boiler cleaning equipment—retractable soot blower

Soot blower SB, SB with PVF 151.00 EA 0 EA 0

Pressure reducing station 70.00 EA 0 EA 0

Trays and channels for supporting tubing 18.00 EA 0 EA 0

Tubing for automatic sequential air operation 40.00 EA 0 EA 0

Air compressor and/or receiver 18.00 Ton 0 Ton 0

Auto sequential panel or air master controller 86.00 Panel 0 Panel 0

IK structural supports 6.00 Blower 0 Blower 0

Bare tube economizer

Tube sections 7.00 Ton 0 Ton 0

Headers 15.00 Ton 0 Ton 0

Integral support steel 28.00 Ton 0 Ton 0

Set rigging for hoisting assemblies 60.00 Boiler 0 Boiler 0

Hoist into place 1.50 Ton 0 Ton 0

Weld tubes to her stubs—(2 < BW 2-1/2 00 3.10 EA 0 EA 0

00

SMAW)

Fit and weld filler bar at tube welds 1.00 Space 0 Space 0

Casing and hoppers including doors 55.00 Ton 0 Ton 0

8.10 Coal-fired boiler installation man-hours

Estimated Actual

BM BM

Install steam drum 0 0

Headers, furnace, and water wall panels 0 0

Install and weld attemperators, superheater, and reheat components 0 0

Tubes, down comers, boiler equipment, burners and diamond soot 0 0

blowers

Coal-fired boiler installation man-hours 0 0