Page 250 - Industrial Wastewater Treatment, Recycling and Reuse

P. 250

224 Industrial Wastewater Treatment, Recycling, and Reuse

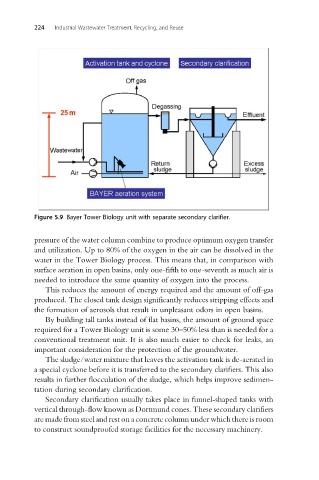

Figure 5.9 Bayer Tower Biology unit with separate secondary clarifier.

pressure of the water column combine to produce optimum oxygen transfer

and utilization. Up to 80% of the oxygen in the air can be dissolved in the

water in the Tower Biology process. This means that, in comparison with

surface aeration in open basins, only one-fifth to one-seventh as much air is

needed to introduce the same quantity of oxygen into the process.

This reduces the amount of energy required and the amount of off-gas

produced. The closed tank design significantly reduces stripping effects and

the formation of aerosols that result in unpleasant odors in open basins.

By building tall tanks instead of flat basins, the amount of ground space

required for a Tower Biology unit is some 30–50% less than is needed for a

conventional treatment unit. It is also much easier to check for leaks, an

important consideration for the protection of the groundwater.

The sludge/water mixture that leaves the activation tank is de-aerated in

a special cyclone before it is transferred to the secondary clarifiers. This also

results in further flocculation of the sludge, which helps improve sedimen-

tation during secondary clarification.

Secondary clarification usually takes place in funnel-shaped tanks with

vertical through-flow known as Dortmund cones. These secondary clarifiers

are made from steel and rest on a concrete column under which there is room

to construct soundproofed storage facilities for the necessary machinery.