Page 254 - Industrial Wastewater Treatment, Recycling and Reuse

P. 254

228 Industrial Wastewater Treatment, Recycling, and Reuse

for high organic load wastewater. To date, a number of Tower Biology units

3

have been constructed to treat between 200 and 90,000 m /day of effluent.

Five of these units are operated by Bayer at its production facilities in Ger-

many, Belgium, India, and the United States. The oldest came on stream in

1979. Tower Biology has also proved effective in other sectors of industry

including brewing, sugar processing, and paper production.

A. Bayer AG, Leverkusen Works (Germany)

The industrial effluent from more than 100 chemical production facilities at

Bayer AG’s Leverkusen works is conveyed through a double sewer more

than 2.5 km long to the “joint sewage treatment plant” in the Leverkusen

suburb of Burrig. A “basin biology” plant with surface aeration has been in

operation there since 1971. This first treatment facility built at Burrig was

able to handle part of the industrial effluent from the Bayer factory as well

as the municipal sewage from the Wupper water authority area. The Bayer

Tower Biology facilities were erected during the second phase of construc-

tion, which began in 1976. This facility went onstream in December 1980.

Since then it has served as the first stage in the biological treatment of the all

the effluent from Bayer’s Leverkusen works; the outlet leads to the basin

biology, the second stage in biological treatment, which deals not only with

the pretreated Bayer effluent but also with the municipal sewage from the

Wupper water authority area (dry weather flow).

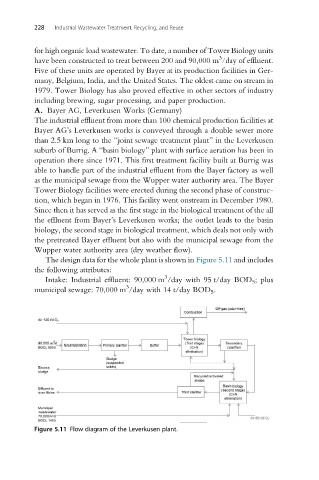

The design data for the whole plant is shown in Figure 5.11 and includes

the following attributes:

3

Intake: Industrial effluent: 90,000 m /day with 95 t/day BOD 5 ; plus

3

municipal sewage: 70,000 m /day with 14 t/day BOD 5 .

Figure 5.11 Flow diagram of the Leverkusen plant.