Page 187 - Inorganic Mass Spectrometry - Fundamentals and Applications

P. 187

I 74 Cristy

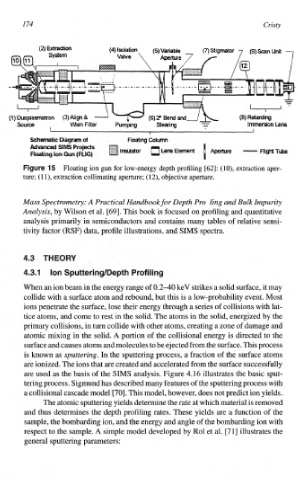

Floating ion gun for lowenergy depth profiling [62]: (lo), extraction aper-

ture; (1 l), extraction collimating aperture; (12), objective aperture.

ass Spectromet~: A Practical andb book for Depth Pro ling and Bulk ~mpuri~

Analysis, by Wilson et al. [69]. This book is focused on profiling and quantitative

analysis primarily in semiconductors and contains many tables of relative sensi-

tivity factor (RSF) data, profile illustrations, and SIMS spectra.

of 0.2-40 keV strikes a solid surface, it may

When an ion beam in the energy range

is

collide with a surface atom and rebound, but this a low-probability event. Most

ions penetrate the surface, lose their energy through a series collisions with lat-

of

tice atoms, and come to rest in the solid. The atoms in the solid, energized by the

of

primary collisions, in turn collide with other atoms, creating a zone damage and

atomic mixing in the solid. A portion of the collisional energy is directed to the

to

be

surface and causes atoms and molecules ejected from the surface. This process

is known as sputter in^. In the sputtering process, a fraction of the surface atoms

are ionized. The ions that are created and accelerated from the surface successfully

are used as the basis of the SIMS analysis. Figure 4.16 illustrates the basic sput-

tering process. Sigmund has described many features of the sputtering process with

a collisional cascade model [70]. This model, however, does not predict ion yields.

is

The atomic sputtering yields determine the rate at which material removed

and thus determines the depth profiling rates. These yields are a function of the

sample, the bo~barding ion, and the energy and angle of the bombarding ion with

respect to the sample. A simple model developed by Rol et al. [71] illustrates the

general sputtering parameters: