Page 123 - Instrumentation Reference Book 3E

P. 123

108 Measurement of force

suitable for both static and dynamic force practice, this method may be used for measuring

measurement. The range of this type of instru- dynamic forces associated with vibrating masses,

ment is from 0.1 N to about 1 kN. It is normally and is discussed further in Chapter 6.

bulky and heavy and tends to be expensive.

7.7 Elastic elements

7.5 Hydraulic pressure

measurement A measuring system basically consists of three

elements; a transducer, a signal conditioner, and

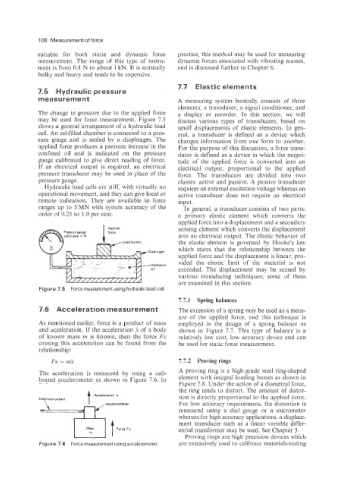

The change in pressure due to the applied force a display or recorder. In this section. we will

may be used for force measurement. Figure 7.5 discuss various types of transducers, based on

shows a general arrangement of a hydraulic load small displacements of elastic elements. In gen-

cell. An oil-filled chamber is connected to a pres- eral, a transducer is defined as a device which

sure gauge and is sealed by a diaphragm. The changes information from one form to another.

applied force produces a pressure increase in the For the purpose of this discussion, a force trans-

confined oil and is indicated on the pressure ducer is defined as a device in which the magni-

gauge calibrated to give direct reading of force. tude of the applied force is converted into an

If an electrical output is required, an electrical electrical output, proportional to the applied

pressure transducer may be used in place of the force. The transducers are divided into two

pressure gauge. classes: active and passive. A passive transducer

Hydraulic load cells are stiff, with virtually no requires an external excitation voltage whereas an

operational movement, and they can give local or active transducer does not require an electrical

remote indication. They are available in force input.

ranges up to 5MN with system accuracy of the In general, a transducer consists of two parts:

order of 0.25 to 1.0 per cent. a primary elastic element which converts the

applied force into a displacement and a secondary

sensing element which converts the displacement

into an electrical output. The elastic behavior of

the elastic element is governed by Hooke's law

which states that the relationship between the

'Diaphragm

applied force and the displacement is linear, pro-

vided the elastic limit of the material is not

-Hydraulic

oil exceeded. The displacement may be sensed by

various transducing techniques; some of them

are examined in this section.

Figure 7.5 Force measurement using hydraulic load cell.

7.7.1 Spring balances

7.6 Acceleration me as u re me n t The extension of a spring may be used as a meas-

ure of the applied force, and this technique is

As mentioned earlier, force is a product of mass employed in the design of a spring balance as

and acceleration If the acceleration x of a body shown in Figure 7.7. This type of balance is a

of known mass in is known, then the force Fx relatively low cost, low accuracy device and can

causing this acceleration can be found from the be used for static force measurement.

relationship:

FX = inx 7.7.2 Proving rings

The acceleration is measured by using a cali- A proving ring is a high-grade steel ring-shaped

brated accelerometer as shown in Figure 7.6. In element with integral loading bosses as shown in

Figure 7.8. Under the action of a diametral force,

t Acceleration x the ring tends to distort. The amount of distor-

tion is directly proportional to the applied force.

Electrical output Accelerometer For low accuracy requirements, the distortion is

I I whereas for high accuracy applications, a displace-

measured using a dial gauge or a micrometer

ment transducer such as a linear variable differ-

My

Force Fx

ential transformer may be used. See Chapter 3.

Proving rings are high precision devices which

Figure 7.6 Force measurement using accelerometer. are extensively used to calibrate materials-testing