Page 127 - Instrumentation Reference Book 3E

P. 127

112 Measurement of force

H I The foregoing has indicated some force-

Incorrect corrsct

measurement methods. Others are many and

varied and no attempt has been made to cover

all types. To simplify the selection of a method

for a particular application, the main para-

meters of the methods discussed are summarized

in Table 7.1.

7.8 Further developments

Advancing technology, improvements in manu-

facturing techniques, and new materials have per-

adcell

mitted increased accuracy and improved design

of bonded strain-gauge load cells since their

introduction about 30 years ago. Microproces-

/I il" sor-enabled and controlled load cells have

n become ubiquitous.

Y New transducing techniques are being con-

Incorrect correct cisrnp

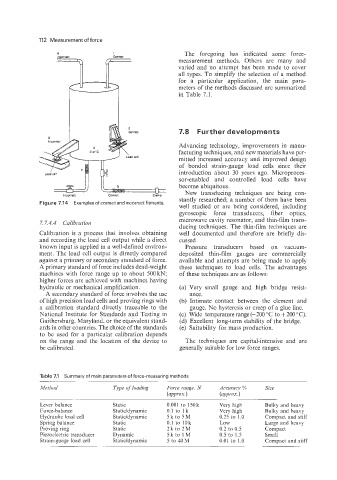

Figure 7.14 Examples of correct and incorrect fitments. stantly researched; a number of them have been

well studied or are being considered, including

gyroscopic force transducers, fiber optics,

7.7.4.4 Calibrutiori microwave cavity resonator, and thin-film trans-

ducing techniques. The thin-film techniques are

Calibration is a process that involves obtaining well documented and therefore are briefly dis-

and recording the load cell output while a direct cussed.

known input is applied in a well-defined environ- Pressure transducers based on vacuum-

ment. The load cell output is directly compared deposited thin-film gauges are commercially

against a primary or secondary standard of force. available and attempts are being made to apply

A primary standard of force includes dead-weight these techniques to load cells. The advantages

machines with force range up to about 500 kN; of these techniques are as follows:

higher forces are achieved with machines having

hydraulic or mechanical amplification. (a) Very small gauge and high bridge resist-

A secondary standard of force involves the use ance.

of high precision load cells and proving rings with (b) Intimate contact between the element and

a calibration standard directly traceable to the gauge. No hysteresis or creep of a glue line.

National Institute for Standards and Testing in (c) Wide temperature range (-200 "C to + 200 "C).

Gaithersburg, Maryland, or the equivalent stand- (d) Excellent long-term stability of the bridge.

ards in other countries. The choice of the standards (e) Suitability for mass production.

to be used for a particular calibration depends

on the range and the location of the device to The techniques are capital-intensive and are

be calibrated. generally suitable for low force ranges.

Table 7.1 Summary of main parameters of force-measuring methods

Method Tvpe of loading Accuracy % Size

(flpprox. )

Lever balance Static 0.001 to 150k Very high Bulky and heavy

Force-balance Static/dynamic 0.1 to 1 k Very high Bulky and heavy

Hydraulic load cell Statiddynamic 5k to 5M 0.25 to 1.0 Compact and stiff

Spring balance Static 0.1 to 10k Low Large and heavy

Proving ring Static 2k to 2M 0.2 to 0.5 Compact

Piezoelectric transducer Dynamic 5ktolM 0.5 to 1.5 Small

Strain-guage load cell Static/dynamic 5 to 40M 0.01 to 1.0 Compact and stiff