Page 129 - Instrumentation Reference Book 3E

P. 129

8 Measurement of density

E. H. HIGHAM AND W. H. BOYES

8.1 General 8.2 Measurement of density

using weight

The measurement and control of liquid density is

critical to a large number of industrial processes. The actual weighing of a sample of known

But although density in itself can be of interest, it volume is perhaps the simplest practical applica-

is usually more important as a way of inferring tion of this principle. Various methods for con-

composition, or concentration of chemicals in tinuous weighing have been devised, but the most

solution, or of solids in suspension. In addition, successful involves the use of a horizontal U-

density is often used as a component in the meas- shaped tube with flexible couplings at a pivot

urement of mass flow. Because the density of point.

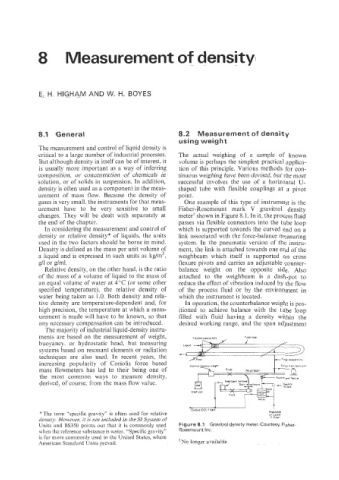

gases is very small, the instruments for that meas- One example of this type of instrument is the

urement have to be very sensitive to small Fisher-Rosemount mark V gravitrol density

changes. They will be dealt with separately at meter? shown in Figure 8.1. In it, the process fluid

the end of the chapter. passes via flexible connectors into the tube loop

In considering the measurement and control of which is supported towards the curved end on a

density or relative density* of liquids, the units link associated with the force-balance measuring

used in the two factors should be borne in mind. system. In the pneumatic version of the instru-

Density is defined as the mass per unit volume of ment, the link is attached towards one end of the

a liquid and is expressed in such units as kg/m3, weighbeam which itself is supported on cross

g/l or glml. flexure pivots and carries an adjustable counter-

Relative density, on the other hand, is the ratio balance weight on the opposite side. Also

of the mass of a volume of liquid to the mass of attached to the weighbeam is a dash-pot to

an equal volume of water at 4°C (or some other reduce the effect of vibration induced by the flow

specified temperature), the relative density of of the process fluid or by the environment in

water being taken as 1.0. Both density and rela- which the instrument is located.

tive density are temperature-dependent and, for In operation, the counterbalance weight is pos-

high precision, the temperature at which a meas- itioned to achieve balance with the tube loop

urement is made will have to be known, so that filled with fluid having a density within the

any necessary compensation can be introduced. desired working range, and the span adjustment

The majority of industrial liquid-density instru-

ments are based on the measurement of weight, Llquid - Tube loop

buoyancy. or hydrostatic head, but measuring

systems based on resonant elements or radiation -

techniques are also used. In recent years, the

increasing popularity of Coriolis force based Counter balance Wwhi

mass flowmeters has led to their being one of

the most common ways to measure density,

derived, of course, from the mass flow value.

OUWA 10 2- 3 bar1

*The term “specific gravity” is often used for relative n3r IUPPl”

Regulated

density. However, it is not included in the SI System of !l 3 bar)

Units and BS350 points out that it is commonly used Figure 8 .I Gravitrol density meter. Courtesy, Fisher-

when the reference substance is water. “Specific gravity” Rosemount Inc.

is far more commonly used in the United States, where

American Standard Units prevail. +No longer available