Page 132 - Instrumentation Reference Book 3E

P. 132

Measurement of density using hydrostatic head 117

9 Overflow Inlet

Densii ’*

signal

Outlet (Relative density= p,) outlet

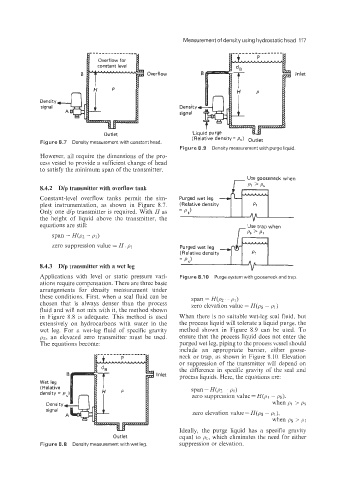

Figure 8.7 Density measurement with constant head

Figure 8.9 Density measurement with purge liquid

However, all require the dimensions of the pro-

cess vessel to provide a sufficient change of head

to satisfy the minimum span of the transmitter.

8.4.2 Dlp transmitter with overflow tank

Constant-level overflow tanks permit the sim-

plest instrumentation, as shown in Figure 8.7.

Only one dip transmitter is required. With H as

the height of liquid above the transmitter, the

equations are still:

span = H(p2 - PI)

zero suppression value = H . pi

8.4.3 Dlp transmitter with a wet leg

Applications with level or static pressure vari- Figure 8.1 0 Purge system with gooseneck and trap.

ations require compensation. There are three basic

arrangements for density measurement under

these conditions. First, when a seal fluid can be

chosen that is always denser than the process span = Wpz - PI)

zero elevation value = H(ps - PI 1

fluid and ill not mix with it, the method shown

in Figure 8.8 is adequate. This method is used When there is no suitable wet-leg seal fluid, but

extensively on hydrocarbons with water in the the process liquid will tolerate a liquid purge, the

wet leg. For a wet-leg fluid of specific gravity method shown in Figure 8.9 can be used. To

ps, an elevated zero transmitter must be used. ensure that the process liquid does not enter the

The equations become: purged wet leg, piping to the process vessel should

include an appropriate barrier, either goose-

neck or trap, as shown in Figure 8.10. Elevation

or suppression of the transmitter will depend on

the difference in specific gravity of the seal and

B 3 Inlet process liquids. Here, the equations are:

Wet leg

(Relative

span = H(p2 - PI)

zero suppression value = H(pl - ps),

when PI > ps

zero elevation value = H(ps - PI).

when PS > PI

Ideally, the purge liquid has a specific gravity

Outlet equal to PI, which eliminates the need for either

Figure 8.8 Densitymeasurement with wet leg suppression or elevation.