Page 130 - Instrumentation Reference Book 3E

P. 130

Measurement of density using buoyancy 115

is set to its mid position. Balance is achieved Transmitter m

when the force applied by the feedback bellows

via the pivot and span-adjustment mechanism to

the weighbeam causes it to take up a position in

which the feedback loop comprising the flapper

nozzle and pneumatic relay generates a pressure

which is both applied to the feedback bellows and ___

used as the output signal. A subsequent increase --

in the density of the process fluid causes a minute -_

--

clockwise rotation of the weighbeani with --

the result that the flapper is brought closer to

the nozzle and so increases the back pressure.

This change is amplified by the relay and applied

to the feedback bellows: which in turn applies an Displacer'

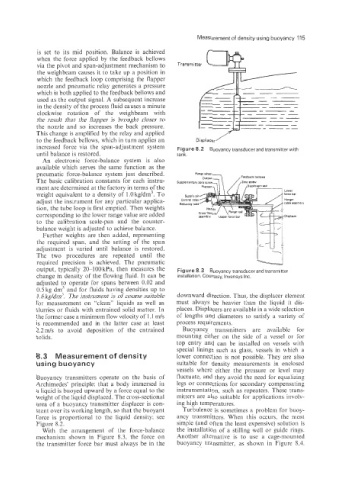

increased force via the span-adjustment system Figure 8.2 Buoyancy transducerandtransmitter with

until balance is restored. tank.

An electronic force-balance system is also

available which serves the same function as the

pneumatic force-balance system just described. Rsnse wheel

,,,",,, 3 ,Feedback bellows

The basic calibration constants for each instru-

ment are determined at the factory in terms of the

weight equivalent to a density of 1 .O kg/dm3. To

adjust the instrument for any particular applica-

tion, the tube loop is first emptied. Then weights

corresponding to the lower range value are added

to the calibration scale-pan and the counter-

balance weight is adjusted to achieve balance.

Further weights are then added, representing

the required span, and the setting of the span

adjustment is varied until balance is restored.

The two procedures are repeated until the

required precision is achieved. The pneumatic

output, typically 20-100 kPa, then measures the Figure 8.3 Buoyancy transducer and transmittel

change in density of the flowing fluid. It can be installation. Courtesy, lnvensys Inc.

adjusted to operate for spans between 0.02 and

0.5kg dm: and for fluids having densities up to

1.6 kg/dm". The instrument is of course suitable downward direction. Thus, the displacer element

for measurement on "'clean" liquids as well as must always be heavier than the liquid it dis-

slurries or fluids with entrained solid matter. In places. Displacers are available in a wide selection

the former case a minimum flow velocity of 1.1 m/s of lengths and diameters to satisfj a variety of

is recommended and in the latter case at least process requirements.

7.2ds to avoid deposition of the entrained Buoyancy transmitters are available for

solids. mounting either on the side of a vessel or for

top entry and can be installed on vessels with

special linings such as glass, vessels in which a

Measurement of density lower connection is not possible. They are also

using buoyancy suitable for density measurements in enclosed

vessels where either the pressure or level may

Buoyancy transmitters operate on the basis of fluctuate, and they avoid the need for equalizing

Archimedes' principle: that a body immersed in legs or connections for secondary compensating

a liquid is buoyed upward by a force equal to the instrumentation, such as repeaters. These trans-

weight of the liquid displaced. The cross-sectional mitters are also suitable for applications involv-

area of a buoyancy transmitter displacer is con- ing high temperatures.

stant over its working length, so that the buoyant Turbulence is sometimes a problem for buoy-

force is proportional to the liquid density; see ancy transmitters. When this occurs, the most

Figure 8.2. simple (and often the least expensive) solution is

With the arrangement of the force-balance the installation of a stilling well or guide rings.

mechanism shown in Figure 8.3, the force on Another alternative is to use a cage-mounted

the transmitter force bar must always be in the buoyancy transmitter, as shown in Figure 8.4.