Page 365 - Instrumentation Reference Book 3E

P. 365

348 Chemical analysis: electrochemical techniques

Where measuring cells are installed in pipe-

work, it is essential that they are positioned in a

rising section of the system to ensure that each

cell is always full of electrolyte, and that pockets

of air are not trapped.

Cleaning and muintenunce .f cells Periodic

inspection and cleaning of conductivity cells is

essential to ensure that the electrode surfaces are

Pipeline or container

free from contamination, which would otherwise

alter the electrode area and effective cell constant.

The frequency of such procedures is mainly

dependent on the nature of the samples but the

design of the cells and the accuracy required for

the measurement will also have to be taken into

consideration. All new cells should be thoroughly

cleaned before installation, and these cleaning

procedures depend on the design of the cell and

the electrode material.

Platinized electrodes Cleaning of these electrodes

constitutes a major drawback in their applica-

tion because no form of mechanical cleaning

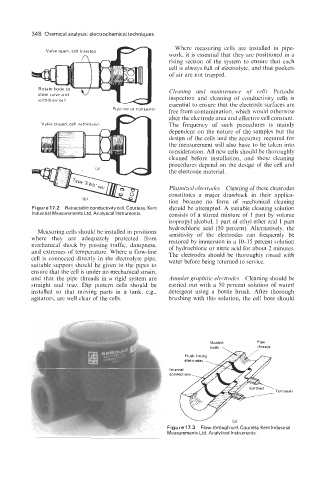

Figure 17.2 Retractable conductivitycell. Courtesy, Kent should be attempted. A suitable cleaning solution

Industrial Measurements Ltd, Analytical Instruments. consists of a stirred mixture of 1 part by volume

isopropyl alcohol, 1 part of ethyl ether and 1 part

hydrochloric acid (50 percent). Alternatively, the

Measuring cells should be installed in positions

where they are adequately protected from sensitivity of the electrodes can frequently be

restored by immersion in a 1&15 percent solution

mechanical shock by passing traffic, dampness, of hydrochloric or nitric acid for about 2 minutes.

and extremes of temperature. Where a flow-line The electrodes should be thoroughly rinsed with

cell is connected directly in the electrolyte pipe, water before being returned to service.

suitable support should be given to the pipes to

ensure that the cell is under no mechanical strain,

and that the pipe threads in a rigid system are Annular graphitic electrodes Cleaning should be

straight and true. Dip pattern cells should be carried out with a 50 percent solution of water/

installed so that moving parts in a tank, e.g., detergent using a bottle brush. After thorough

agitators, are well clear of the cells. brushing with this solution, the cell bore should

- . ..

Molded Pipe

$reads

Figure 17.3 Flow-through cell. Courtesy Kent Industrial

Measurements Ltd. Analytical Instruments.