Page 370 - Instrumentation Reference Book 3E

P. 370

Electrical conductivity 353

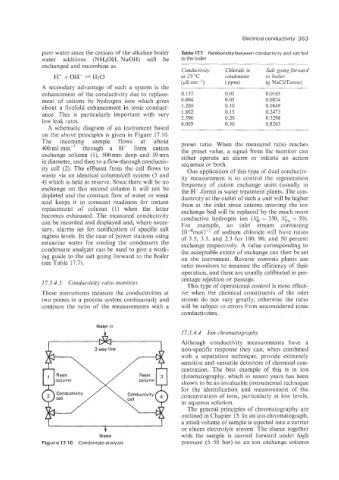

pure water since the cations of the alkaline boiler Table 17.7 Relationship between conductivity and salt fed

water additives (NH40H, NaOH) will be to the boiler

exchanged and recombine as

Conductivity Chloride in Salt going forward

+ OM- + H20 at 25°C condensate to boiler

(ps cm-') ( PPm) (g NaCl/Tonne)

A secondary advantage of such a system is the

enhancement of the conductivity due to replace- 0.137 0.01 0.0165

ment of cations by hydrogen ions which gives 0.604 0.05 0.0824

about a fivefold enhancement in ionic conduct- 1.200 0.10 0.1649

1.802

ance. This is particularly important with very 2.396 0.15 0.2473

0.3298

0.20

low leak rates. 6.003 0.50 0.8265

A schematic diagram of an instrument based

on the above principles is given in Figure 17.10.

The incoming sample flows at about preset ratio. When the measured ratio reaches

400ml min-* through a H+ form cation the preset value, a signal from the monitor can

exchange column (l), 500mm deep and 50mm either operate an alarm or initiate an action

in diameter, and then to a flow-through conductiv- sequence or both.

ity cell (2). The effluent from the cell flows to One application of this type of dual conductiv-

waste via an identical columnkell system (3 and ity measurement is to control the regeneration

4) which is held in reserve. Since there will be no frequency of cation exchange units (usually in

exchange on this second column it will not be the H+-form) in water treatment plants. The con-

depleted and the constant flow of water or weak ductivity at the outlet of such a unit will be higher

acid keeps it in constant readiness for instant than at the inlet since cations entering the ion

replacement of column (1) when the latter exchange bed will be replaced by the much more

becomes exhausted. The measured conductivity conductive hydrogen ion (A& = 350, A&, = 50).

can be recorded and displayed and, where neces- For example, an inlet stream containing

sary, alarms set for notification of specific salt 10-4mol I-' of sodium chloride will have ratios

ingress levels. In the case of power stations using of 3.5, 3.3, and 2.3 for 100, 90, and 50 percent

estuarine water for cooling the condensers the exchange respectively. A value corresponding to

condensate analyzer can be used to give a work- the acceptable extent of exchange can then be set

ing guide to the salt going forward to the boiler on the instrument. Reverse osmosis plants use

(see Table 17.7). ratio monitors to measure the efficiency of their

operation, and these are usually calibrated in per-

centage rejection or passage.

17.3.4.3 Conductivity ratio monitors

This type of operational control is most effect-

These instruments measure the conductivities at ive when the chemical constituents of the inlet

two points in a process system continuously and stream do not vary greatly; otherwise the ratio

compare the ratio of the measurements with a will be subject to errors from unconsidered ionic

conductivities.

Water in

1 17.3.4.4 Ion chromatography

Although conductivity measurements have a

non-specific response they can, when combined

with a separation technique, provide extremely

sensitive and versatile detectors of chemical con-

centration. The best example of this is in ion

chromatography, which in recent years has been

shown to be an invaluable instrumental technique

for the identification and measurement of the

concentration of ions, particularly at low levels,

in aqueous solution.

The general principles of chromatography are

outlined in Chapter 15. In an ion chromatograph,

a small volume of sample is injected into a carrier

1

or eluent electrolyte stream. The eluent together

Waste with the sample is carried forward under high

Figure 17.10 Condensate analyzer. pressure (5-50 bar) to an ion exchange column