Page 74 - Instrumentation Reference Book 3E

P. 74

Practice of length measurement for industrial use 59

porating manually or automatically read optical

scales. Figure 3.7 shows the modern form of such

measuring machines. This is capable of a guaran-

teed accuracy of around 1 pm in length measure-

ments up to its full range capability of 300mm.

Larger machines are also made covering the

range of around 4m: these machines have also

been adapted to provide electronic readout; see

Section 3.6.

Where measurement of complex shapes is

important, the use of measuring machines can

be quite tedious; more speedy, direct methods

can be used when the accuracy needed is not of

the highest limits. In this aspect of tool-room

measurement the optical profile projector may

be applicable.

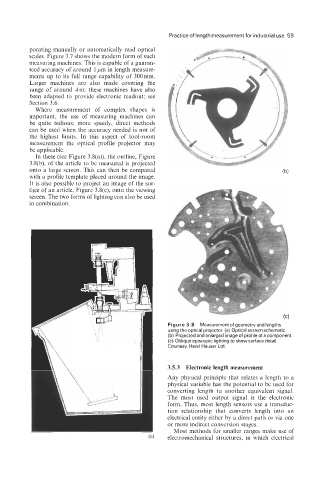

In these (see Figure 3.8(a)), the outline, Figure

3.8(b), of the article to be measured is projected

onto a large screen. This can then be compared

with a profile template placed around the image.

It is also possible to project an image of the sur-

face of an article, Figure 3.8(c), onto the viewing

screen. The two forms of lighting can also be used

in combination.

Figure 3.8 Measurement of geometryand lengths

using the optical projector. (a) Optical system schematic.

(b) Projected and enlarged image of profile of a component.

(c) Oblique episcopic lighting to show surface detail.

Courtesy, Henri Hauser Ltd.

3.5.3 Electronic length measurement

Any physical principle that relates a length to a

physical variable has the potential to be used for

converting length to another equivalent signal.

The most used output signal is the electronic

form. Thus, most length sensors use a transduc-

tion relationship that converts length into an

electrical entity either by a direct path or via one

or more indirect conversion stages.

Most methods for smaller ranges make use of

electromechanical structures, in which electrical