Page 76 - Instrumentation Reference Book 3E

P. 76

Practice of length measurement for industrial use 61

alternative inductive and capacitive methods; the Interroyatio~

impedance of a resistance unit set to give fine

discrimination generally is required to be high

with subsequent inherent resistance noise gener-

ation. These units are variously described in most

general instrumentation texts. The alternative

method, Figure 3.9(b), makes use of strain of

the bulk properties of the resistance, the most (3)

used method being the resistance strain gauge. Induction depends on

number of turns

As strain gauges are the subject of Chapter 4 they

will not be discussed further at this stage.

An alternative bulk resistance method that

sometimes has application is to use a material,

such as carbon in disc form, using the input

length change to alter the force of surface contact

between the discs. This alters the pile resistance.

The method requires considerable force from the

input and, therefore, has restricted application. It ( b)

does, however, have high electric current-carrying

capability and can often be used to drive directly Input

quite powerful control circuits without the need

for electronic amplification. The bulk properties 'rogation CilCUlfry

method can only transduce small relative length

changes of an interval. Practical reasons generally

restrict its use to gauge intervals of a few milli- VsrVlny COupliny

meters and to strains of that interval of around 1 between coils

percent.

armatUre (C)

3.5.3.2 Electrical magnetic inductive processes in coils

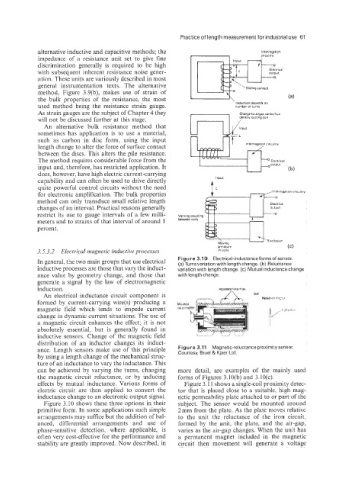

Figure 3.1 0 Electrical-inductance forms of sensor.

In general, the two main groups that use electrical (a) Turnsvariation with length change. (b) Reluctance

inductive processes are those that vary the induct- variation with length change. (c) Mutual inductance change

ance value by geometry change, and those that with length change.

generate a signal by the law of electromagnetic

induction.

An electrical inductance circuit component is

formed by current-carrying wire(s) producing a

magnetic field which tends to impede current

change in dynamic current situations. The use of

a magnetic circuit enhances the effect; it is not

absolutely essential, but is generally found in

inductive sensors. Change of the magnetic field

distribution of an inductor changes its induct-

ance. Length sensors make use of this principle Figure 3.11 Magnetic-reluctance proximity sensor.

Courtesy, Bruel & Kjaer Ltd.

by using a. length change of the mechanical struc-

ture of an inductance to vary the inductance. This

can be achieved by varying the turns, changing more detail, are examples of the mainly used

the magnetic circuit reluctance, or by inducing forms of Figures 3.10(b) and 3.10(c).

effects by mutual inductance. Various forms of Figure 3.11 shows a single-coil proximity detec-

electric circuit are then applied to convert the tor that is placed close to a suitable, high mag-

inductance change to an electronic output signal. netic permeability plate attached to or part of the

Figure 3.10 shows these three options in their subject. The sensor would be mounted around

primitive form. In some applications such simple 2 mm from the plate. As the plate moves relative

arrangements may suffice but the addition of bal- to the unit the reluctance of the iron circuit;

anced, differential arrangements and use of formed by the unit, the plate, and the air-gap,

phase-sensitive detection, where applicable, is varies as the air-gap changes. When the unit has

often very cost-effective for the performance and a permanent magnet included in the magnetic

stability are greatly improved. Now described, in circuit then movement will generate a voltage