Page 241 - Intelligent Digital Oil And Gas Fields

P. 241

Workflow Automation and Intelligent Control 191

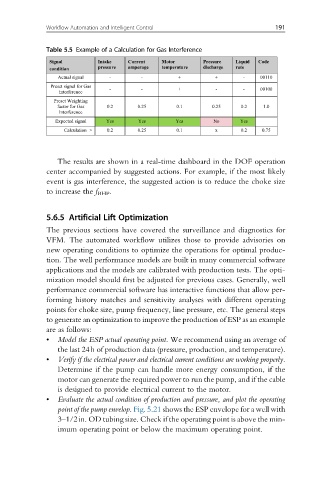

Table 5.5 Example of a Calculation for Gas Interference

The results are shown in a real-time dashboard in the DOF operation

center accompanied by suggested actions. For example, if the most likely

event is gas interference, the suggested action is to reduce the choke size

to increase the f BHP .

5.6.5 Artificial Lift Optimization

The previous sections have covered the surveillance and diagnostics for

VFM. The automated workflow utilizes those to provide advisories on

new operating conditions to optimize the operations for optimal produc-

tion. The well performance models are built in many commercial software

applications and the models are calibrated with production tests. The opti-

mization model should first be adjusted for previous cases. Generally, well

performance commercial software has interactive functions that allow per-

forming history matches and sensitivity analyses with different operating

points for choke size, pump frequency, line pressure, etc. The general steps

to generate an optimization to improve the production of ESP as an example

are as follows:

• Model the ESP actual operating point. We recommend using an average of

the last 24h of production data (pressure, production, and temperature).

• Verify if the electrical power and electrical current conditions are working properly.

Determine if the pump can handle more energy consumption, if the

motor can generate the required power to run the pump, and if the cable

is designed to provide electrical current to the motor.

• Evaluate the actual condition of production and pressure, and plot the operating

point of the pump envelop. Fig. 5.21 shows the ESP envelope for a well with

3–1/2in. OD tubing size. Check if the operating point is above the min-

imum operating point or below the maximum operating point.