Page 277 - Intelligent Digital Oil And Gas Fields

P. 277

Integrated Asset Management and Optimization Workflows 227

Field process

model (dynamic

coupling)

Vertical lift performance table

Reservior Fluid properties @ P and T Network

simulator t 0 (time step) models

CPU time t 1

fBHP does not meet

Res sandface pressure

t

Reservior n+1 Network

simulator models

fBHP meets Res

sandface pressure

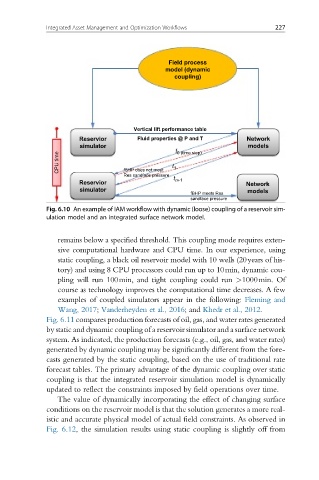

Fig. 6.10 An example of IAM workflow with dynamic (loose) coupling of a reservoir sim-

ulation model and an integrated surface network model.

remains below a specified threshold. This coupling mode requires exten-

sive computational hardware and CPU time. In our experience, using

static coupling, a black oil reservoir model with 10 wells (20years of his-

tory) and using 8 CPU processors could run up to 10min, dynamic cou-

pling will run 100min, and tight coupling could run >1000min. Of

course as technology improves the computational time decreases. A few

examples of coupled simulators appear in the following: Fleming and

Wang, 2017; Vanderheyden et al., 2016;and Khedr et al., 2012.

Fig. 6.11 compares production forecasts of oil, gas, and water rates generated

by static and dynamic coupling of a reservoir simulator and a surface network

system. As indicated, the production forecasts (e.g., oil, gas, and water rates)

generated by dynamic coupling may be significantly different from the fore-

casts generated by the static coupling, based on the use of traditional rate

forecast tables. The primary advantage of the dynamic coupling over static

coupling is that the integrated reservoir simulation model is dynamically

updated to reflect the constraints imposed by field operations over time.

The value of dynamically incorporating the effect of changing surface

conditions on the reservoir model is that the solution generates a more real-

istic and accurate physical model of actual field constraints. As observed in

Fig. 6.12, the simulation results using static coupling is slightly off from