Page 274 - Intelligent Digital Oil And Gas Fields

P. 274

224 Intelligent Digital Oil and Gas Fields

Noise Input System Output Noise

(reservoir, wells

& facilities)

Controllable

input Optimization

Control Sensors

algorithms

System model

Parameter

updating

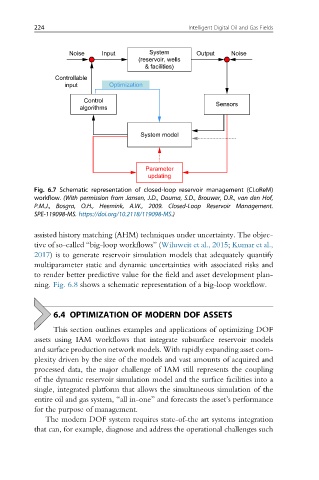

Fig. 6.7 Schematic representation of closed-loop reservoir management (CLoReM)

workflow. (With permission from Jansen, J.D., Douma, S.D., Brouwer, D.R., van den Hof,

P.M.J., Bosgra, O.H., Heemink, A.W., 2009. Closed-Loop Reservoir Management.

SPE-119098-MS. https://doi.org/10.2118/119098-MS.)

assisted history matching (AHM) techniques under uncertainty. The objec-

tive of so-called “big-loop workflows” (Wiluweit et al., 2015; Kumar et al.,

2017) is to generate reservoir simulation models that adequately quantify

multiparameter static and dynamic uncertainties with associated risks and

to render better predictive value for the field and asset development plan-

ning. Fig. 6.8 shows a schematic representation of a big-loop workflow.

6.4 OPTIMIZATION OF MODERN DOF ASSETS

This section outlines examples and applications of optimizing DOF

assets using IAM workflows that integrate subsurface reservoir models

and surface production network models. With rapidly expanding asset com-

plexity driven by the size of the models and vast amounts of acquired and

processed data, the major challenge of IAM still represents the coupling

of the dynamic reservoir simulation model and the surface facilities into a

single, integrated platform that allows the simultaneous simulation of the

entire oil and gas system, “all in-one” and forecasts the asset’s performance

for the purpose of management.

The modern DOF system requires state-of-the art systems integration

that can, for example, diagnose and address the operational challenges such