Page 92 - Intro Predictive Maintenance

P. 92

Machine-Train Monitoring Parameters 83

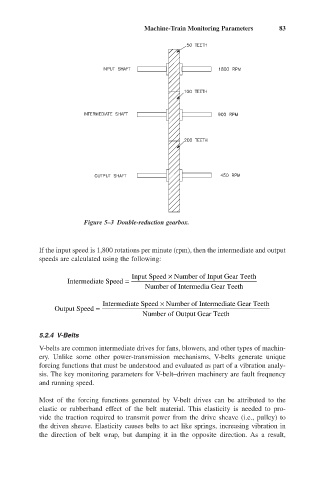

Figure 5–3 Double-reduction gearbox.

If the input speed is 1,800 rotations per minute (rpm), then the intermediate and output

speeds are calculated using the following:

¥

Input Speed Number of Input Gear Teeth

Intermediate Speed =

Number of Intermedia Gear Teeth

¥

Intermediate Speed Number of Intermediate Gear Teeth

Output Speed =

Number of Output Gear Teeth

5.2.4 V-Belts

V-belts are common intermediate drives for fans, blowers, and other types of machin-

ery. Unlike some other power-transmission mechanisms, V-belts generate unique

forcing functions that must be understood and evaluated as part of a vibration analy-

sis. The key monitoring parameters for V-belt–driven machinery are fault frequency

and running speed.

Most of the forcing functions generated by V-belt drives can be attributed to the

elastic or rubberband effect of the belt material. This elasticity is needed to pro-

vide the traction required to transmit power from the drive sheave (i.e., pulley) to

the driven sheave. Elasticity causes belts to act like springs, increasing vibration in

the direction of belt wrap, but damping it in the opposite direction. As a result,