Page 96 - Intro Predictive Maintenance

P. 96

Machine-Train Monitoring Parameters 87

FIRST-STAGE FIRST-STAGE CONDENSATE

DIFFUSER INTERCOOLER SEPARATOR

SECOND-

FIRST-STAGE STAGE

ROTOR

INLET

FIRST-

STAGE

INLET

BULL- -

GEAR

THIRD-

STAGE

INLET

FOURTH-STAGE

ROTOR

FOURTH-

STAGE

AFTERCOOLER

DISCHARGE INLET

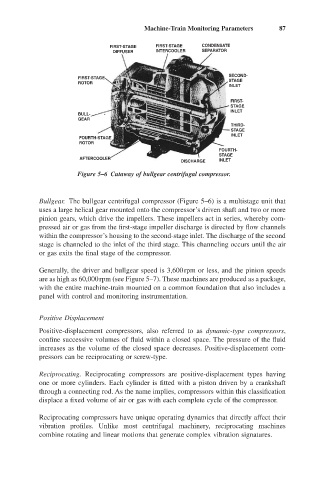

Figure 5–6 Cutaway of bullgear centrifugal compressor.

Bullgear. The bullgear centrifugal compressor (Figure 5–6) is a multistage unit that

uses a large helical gear mounted onto the compressor’s driven shaft and two or more

pinion gears, which drive the impellers. These impellers act in series, whereby com-

pressed air or gas from the first-stage impeller discharge is directed by flow channels

within the compressor’s housing to the second-stage inlet. The discharge of the second

stage is channeled to the inlet of the third stage. This channeling occurs until the air

or gas exits the final stage of the compressor.

Generally, the driver and bullgear speed is 3,600rpm or less, and the pinion speeds

are as high as 60,000rpm (see Figure 5–7). These machines are produced as a package,

with the entire machine-train mounted on a common foundation that also includes a

panel with control and monitoring instrumentation.

Positive Displacement

Positive-displacement compressors, also referred to as dynamic-type compressors,

confine successive volumes of fluid within a closed space. The pressure of the fluid

increases as the volume of the closed space decreases. Positive-displacement com-

pressors can be reciprocating or screw-type.

Reciprocating. Reciprocating compressors are positive-displacement types having

one or more cylinders. Each cylinder is fitted with a piston driven by a crankshaft

through a connecting rod. As the name implies, compressors within this classification

displace a fixed volume of air or gas with each complete cycle of the compressor.

Reciprocating compressors have unique operating dynamics that directly affect their

vibration profiles. Unlike most centrifugal machinery, reciprocating machines

combine rotating and linear motions that generate complex vibration signatures.