Page 95 - Intro Predictive Maintenance

P. 95

86 An Introduction to Predictive Maintenance

5.3 DRIVEN COMPONENTS

This module cannot effectively discuss all possible combinations of driven compo-

nents that may be found in a plant; however, the guidelines provided in this section

can be used to evaluate most of the machine-trains and process systems that are

typically included in a microprocessor-based vibration-monitoring program.

5.3.1 Compressors

There are two basic types of compressors: centrifugal and positive displacement. Both

of these major classifications can be further divided into subtypes, depending on their

operating characteristics. This section provides an overview of the more common

centrifugal and positive-displacement compressors.

Centrifugal

There are two types of commonly used centrifugal compressors: inline and bullgear.

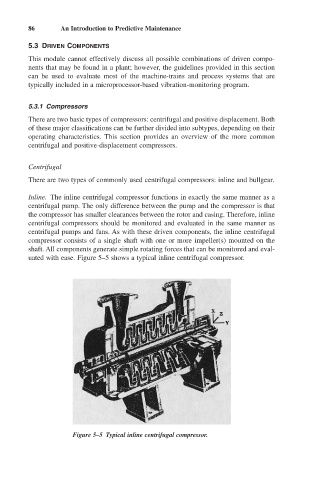

Inline. The inline centrifugal compressor functions in exactly the same manner as a

centrifugal pump. The only difference between the pump and the compressor is that

the compressor has smaller clearances between the rotor and casing. Therefore, inline

centrifugal compressors should be monitored and evaluated in the same manner as

centrifugal pumps and fans. As with these driven components, the inline centrifugal

compressor consists of a single shaft with one or more impeller(s) mounted on the

shaft. All components generate simple rotating forces that can be monitored and eval-

uated with ease. Figure 5–5 shows a typical inline centrifugal compressor.

Figure 5–5 Typical inline centrifugal compressor.