Page 98 - Intro Predictive Maintenance

P. 98

Machine-Train Monitoring Parameters 89

Suction Stroke Compression Stroke

Suction Discharge

Valve Valve

A

Clearance Space Expansion B Suction C Compression D Delivery or Discharge E

Piston at Top

Dead Center Piston at Bottom

Dead Center

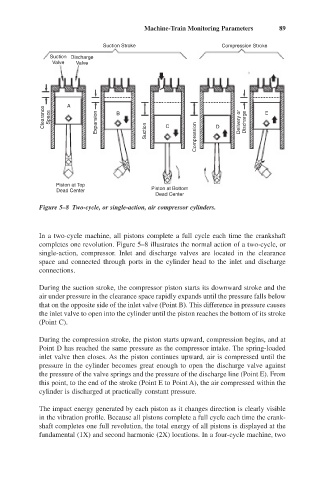

Figure 5–8 Two-cycle, or single-action, air compressor cylinders.

In a two-cycle machine, all pistons complete a full cycle each time the crankshaft

completes one revolution. Figure 5–8 illustrates the normal action of a two-cycle, or

single-action, compressor. Inlet and discharge valves are located in the clearance

space and connected through ports in the cylinder head to the inlet and discharge

connections.

During the suction stroke, the compressor piston starts its downward stroke and the

air under pressure in the clearance space rapidly expands until the pressure falls below

that on the opposite side of the inlet valve (Point B). This difference in pressure causes

the inlet valve to open into the cylinder until the piston reaches the bottom of its stroke

(Point C).

During the compression stroke, the piston starts upward, compression begins, and at

Point D has reached the same pressure as the compressor intake. The spring-loaded

inlet valve then closes. As the piston continues upward, air is compressed until the

pressure in the cylinder becomes great enough to open the discharge valve against

the pressure of the valve springs and the pressure of the discharge line (Point E). From

this point, to the end of the stroke (Point E to Point A), the air compressed within the

cylinder is discharged at practically constant pressure.

The impact energy generated by each piston as it changes direction is clearly visible

in the vibration profile. Because all pistons complete a full cycle each time the crank-

shaft completes one full revolution, the total energy of all pistons is displayed at the

fundamental (1X) and second harmonic (2X) locations. In a four-cycle machine, two