Page 278 - Introduction to Colloid and Surface Chemistry

P. 278

Emulsions and foams 267

(bj I H" Io7( ~—"—

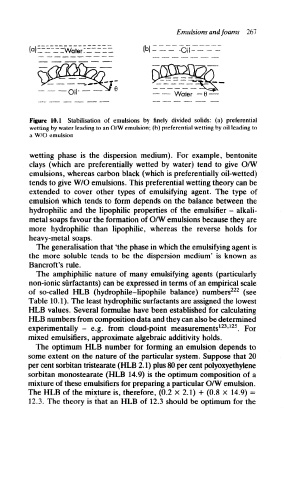

Figure 10.1 Stabilisation of emulsions by finely divided solids: (a) preferential

wetting by water leading to an O/W emulsion; (b) preferential wetting by oil leading to

a W/O emulsion

wetting phase is the dispersion medium). For example, bentonite

clays (which are preferentially wetted by water) tend to give O/W

emulsions, whereas carbon black (which is preferentially oil-wetted)

tends to give W/O emulsions. This preferential wetting theory can be

extended to cover other types of emulsifying agent. The type of

emulsion which tends to form depends on the balance between the

hydrophilic and the lipophilic properties of the emulsifier - alkali-

metal soaps favour the formation of O/W emulsions because they are

more hydrophilic than lipophilic, whereas the reverse holds for

heavy-metal soaps.

The generalisation that 'the phase in which the emulsifying agent is

the more soluble tends to be the dispersion medium' is known as

Bancroft's rule.

The amphiphilic nature of many emulsifying agents (particularly

non-ionic surfactants) can be expressed in terms of an empirical scale

of so-called HLB (hydrophile-lipophile balance) numbers 222 (see

Table 10.1). The least hydrophilic surfactants are assigned the lowest

HLB values. Several formulae have been established for calculating

HLB numbers from composition data and they can also be determined

'

experimentally - e.g. from cloud-point measurements 123 125 . For

mixed emulsifiers, approximate algebraic additivity holds.

The optimum HLB number for forming an emulsion depends to

some extent on the nature of the particular system. Suppose that 20

per cent sorbitan tristearate (HLB 2.1) plus 80 per cent polyoxyethylene

sorbitan monostearate (HLB 14.9) is the optimum composition of a

mixture of these emulsifiers for preparing a particular O/W emulsion.

The HLB of the mixture is, therefore, (0.2 x 2.1) + (0.8 x 14.9) =

12.3. The theory is that an HLB of 12.3 should be optimum for the