Page 279 - Introduction to Colloid and Surface Chemistry

P. 279

268 Emulsions and foams

formation of this particular O/W emulsion by use of other emulsifier

systems; for example, the optimum proportions in a mixture of

sorbitan mono-oleate (HLB 4.3) and polyoxyethylene sorbitan

monopalmitate (HLB 15.6) should be approximately 30 per cent and

70 per cent, respectively. In commercial emulsion formulation, HLB

numbers are used advantageously in this way as an initial guide prior

to a certain amount of trial and error testing.

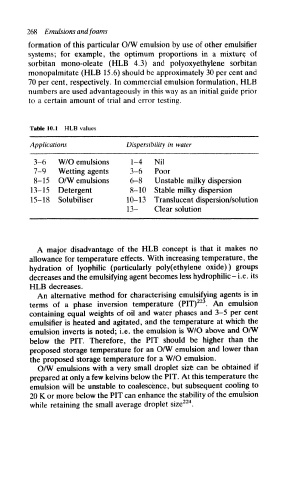

Table 10.1 HLB values

Applications Dispersibility in water

3-6 W/O emulsions 1-4 Nil

7-9 Wetting agents 3-6 Poor

8-15 O/W emulsions 6-8 Unstable milky dispersion

13-15 Detergent 8-10 Stable milky dispersion

15-18 Solubiliser 10-13 Translucent dispersion/solution

13- Clear solution

A major disadvantage of the HLB concept is that it makes no

allowance for temperature effects. With increasing temperature, the

hydration of lyophilic (particularly poly(ethylene oxide)) groups

decreases and the emulsifying agent becomes less hydrophilic- i.e. its

HLB decreases.

An alternative method for characterising emulsifying agents is in

223

terms of a phase inversion temperature (PIT) . An emulsion

containing equal weights of oil and water phases and 3-5 per cent

emulsifier is heated and agitated, and the temperature at which the

emulsion inverts is noted; i.e. the emulsion is W/O above and O/W

below the PIT. Therefore, the PIT should be higher than the

proposed storage temperature for an O/W emulsion and lower than

the proposed storage temperature for a W/O emulsion.

O/W emulsions with a very small droplet size can be obtained if

prepared at only a few kelvins below the PIT. At this temperature the

emulsion will be unstable to coalescence, but subsequent cooling to

20 K or more below the PIT can enhance the stability of the emulsion

224

while retaining the small average droplet size .