Page 192 - Introduction to Information Optics

P. 192

3.2. Light Propagation in Optical Fibers

Preform

Furnace

Diameter

i i n r~y monitor

Ji-, Coater for jacket

Drawing

tractors

Tensile-strength

monitor

Winding

• | drum

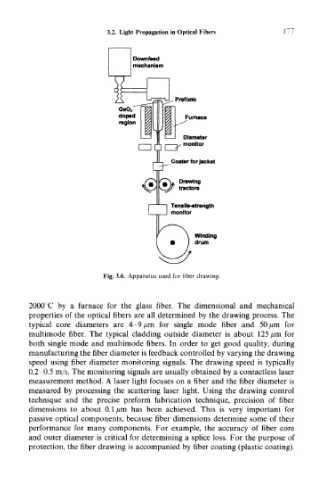

Fig. 3.6. Apparatus used for fiber drawing.

2000°C by a furnace for the glass fiber. The dimensional and mechanical

properties of the optical fibers are all determined by the drawing process. The

typical core diameters are 4-9 jum for single mode fiber and 50 /mi for

multimode fiber. The typical cladding outside diameter is about 125 /mi for

both single mode and multimode fibers. In order to get good quality, during

manufacturing the fiber diameter is feedback controlled by varying the drawing

speed using fiber diameter monitoring signals. The drawing speed is typically

0.2-0.5 m/s. The monitoring signals are usually obtained by a contactless laser

measurement method. A laser light focuses on a fiber and the fiber diameter is

measured by processing the scattering laser light. Using the drawing control

technique and the precise preform fabrication technique, precision of fiber

dimensions to about 0.1 ^.m has been achieved. This is very important for

passive optical components, because fiber dimensions determine some of their

performance for many components. For example, the accuracy of fiber core

and outer diameter is critical for determining a splice loss. For the purpose of

protection, the fiber drawing is accompanied by fiber coating (plastic coating).