Page 220 - Introduction to Petroleum Engineering

P. 220

ONSHORE FACILITIES 207

Storage tanks

Separator

Pump

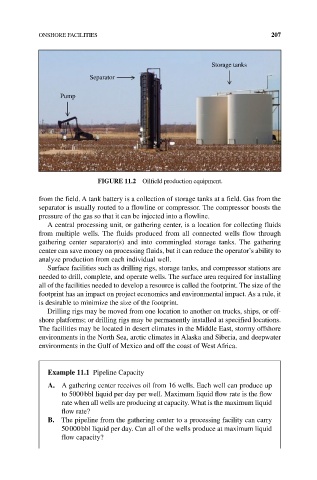

FIgURE 11.2 Oilfield production equipment.

from the field. A tank battery is a collection of storage tanks at a field. Gas from the

separator is usually routed to a flowline or compressor. The compressor boosts the

pressure of the gas so that it can be injected into a flowline.

A central processing unit, or gathering center, is a location for collecting fluids

from multiple wells. The fluids produced from all connected wells flow through

gathering center separator(s) and into commingled storage tanks. The gathering

center can save money on processing fluids, but it can reduce the operator’s ability to

analyze production from each individual well.

Surface facilities such as drilling rigs, storage tanks, and compressor stations are

needed to drill, complete, and operate wells. The surface area required for installing

all of the facilities needed to develop a resource is called the footprint. The size of the

footprint has an impact on project economics and environmental impact. As a rule, it

is desirable to minimize the size of the footprint.

Drilling rigs may be moved from one location to another on trucks, ships, or off-

shore platforms; or drilling rigs may be permanently installed at specified locations.

The facilities may be located in desert climates in the Middle East, stormy offshore

environments in the North Sea, arctic climates in Alaska and Siberia, and deepwater

environments in the Gulf of Mexico and off the coast of West Africa.

Example 11.1 Pipeline Capacity

A. A gathering center receives oil from 16 wells. Each well can produce up

to 5000 bbl liquid per day per well. Maximum liquid flow rate is the flow

rate when all wells are producing at capacity. What is the maximum liquid

flow rate?

B. The pipeline from the gathering center to a processing facility can carry

50 000 bbl liquid per day. Can all of the wells produce at maximum liquid

flow capacity?