Page 299 - Introduction to chemical reaction engineering and kinetics

P. 299

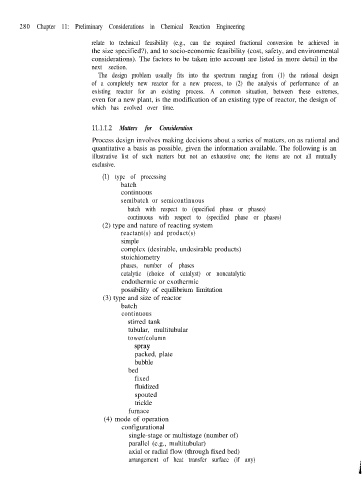

280 Chapter 11: Preliminary Considerations in Chemical Reaction Engineering

relate to technical feasibility (e.g., can the required fractional conversion be achieved in

the size specified?), and to socio-economic feasibility (cost, safety, and environmental

considerations). The factors to be taken into account are listed in more detail in the

next section.

The design problem usually fits into the spectrum ranging from (1) the rational design

of a completely new reactor for a new process, to (2) the analysis of performance of an

existing reactor for an existing process. A common situation, between these extremes,

even for a new plant, is the modification of an existing type of reactor, the design of

which has evolved over time.

11.1.1.2 Matters for Consideration

Process design involves making decisions about a series of matters, on as rational and

quantitative a basis as possible, given the information available. The following is an

illustrative list of such matters but not an exhaustive one; the items are not all mutually

exclusive.

(1) type of processing

batch

continuous

semibatch or semicontinuous

batch with respect to (specified phase or phases)

continuous with respect to (specified phase or phases)

(2) type and nature of reacting system

reactant(s) and product(s)

simple

complex (desirable, undesirable products)

stoichiometry

phases, number of phases

catalytic (choice of catalyst) or noncatalytic

endothermic or exothermic

possibility of equilibrium limitation

(3) type and size of reactor

batch

continuous

stirred tank

tubular, multitubular

tower/column

spray

packed, plate

bubble

bed

fixed

fluidized

spouted

trickle

furnace

(4) mode of operation

configurational

single-stage or multistage (number of)

parallel (e.g., multitubular)

axial or radial flow (through fixed bed)

arrangement of heat transfer surface (if any)