Page 302 - Introduction to chemical reaction engineering and kinetics

P. 302

11.2 Examples of Reactors for Illustration of Process Design Considerations 283

11.1.2 Mechanical Design

The distinction between process design (as outlined in Section 11.1.1) and “mechanical”

design (most other aspects!) is somewhat arbitrary. However, in the latter we include

the following, which, although important, are outside our scope in this book (see Perry,

et al., 1984; Peters and Timmerhaus, 1991):

impeller or agitator design (as in a stirred tank)

power requirement (for above)

reactor-as-pressure-vessel design

wall thickness

over-pressure relief

fabrication

support-structure design

maintenance features

11.2 EXAMPLES OF REACTORS FOR ILLUSTRATION OF PROCESS

DESIGN CONSIDERATIONS

Reactors exist in a variety of types with differing modes of operation for various pro-

cesses and reacting systems. Figures 11.1 to 11.8 illustrate a number of these, some in a

schematic, generic sense, and some for specific processes.

11.2.1 Batch Reactors

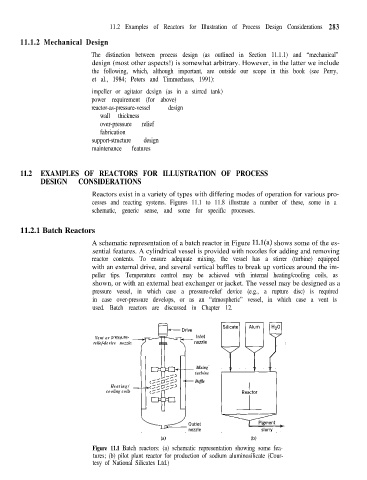

A schematic representation of a batch reactor in Figure ll.l(a) shows some of the es-

sential features. A cylindrical vessel is provided with nozzles for adding and removing

reactor contents. To ensure adequate mixing, the vessel has a stirrer (turbine) equipped

with an external drive, and several vertical baffles to break up vortices around the im-

peller tips. Temperature control may be achieved with internal heating/cooling coils, as

shown, or with an external heat exchanger or jacket. The vessel may be designed as a

pressure vessel, in which case a pressure-relief device (e.g., a rupture disc) is required

in case over-pressure develops, or as an “atmospheric” vessel, in which case a vent is

used. Batch reactors are discussed in Chapter 12.

Vent or pressure-

relief-device nozzle

Mixing

turbine

Baffle

Heating/ _

cooling coils

(a) (b)

Figure 11.1 Batch reactors: (a) schematic representation showing some fea-

tures; (b) pilot plant reactor for production of sodium aluminosilicate (Cour-

tesy of National Silicates Ltd.)