Page 305 - Introduction to chemical reaction engineering and kinetics

P. 305

286 Chapter 11: Preliminary Considerations in Chemical Reaction Engineering

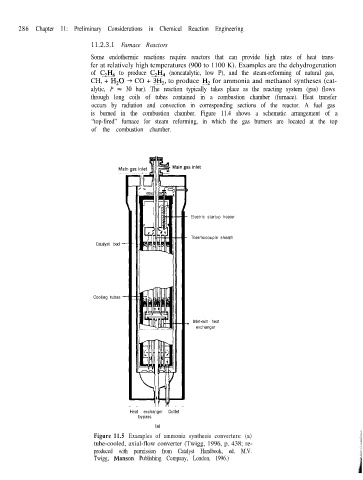

11.2.3.1 Furnace Reactors

Some endothermic reactions require reactors that can provide high rates of heat trans-

fer at relatively high temperatures (900 to 1100 K). Examples are the dehydrogenation

of C,H6 to produce C,H, (noncatalytic, low P), and the steam-reforming of natural gas,

CH, + H,O -+ CO + 3H,, to produce Hz for ammonia and methanol syntheses (cat-

alytic, P = 30 bar). The reaction typically takes place as the reacting system (gas) flows

through long coils of tubes contained in a combustion chamber (furnace). Heat transfer

occurs by radiation and convection in corresponding sections of the reactor. A fuel gas

is burned in the combustion chamber. Figure 11.4 shows a schematic arrangement of a

“top-fired” furnace for steam reforming, in which the gas burners are located at the top

of the combustion chamber.

Electric startup heater

Thermocouple sheath

Catalyst bed

Cooling tubes

_ Inlet-exit heat

exchanger

Heat exchanger Outlet

bypass

(a)

Figure 11.5 Examples of ammonia synthesis converters: (a)

tube-cooled, axial-flow converter (Twigg, 1996, p. 438; re-

produced with permission from Catalyst Handbook, ed. M.V.

Twigg, Manson Publishing Company, London, 1996.)