Page 310 - Introduction to chemical reaction engineering and kinetics

P. 310

11.2 Examples of Reactors for Illustration of Process Design Considerations 291

velocity allows for partial disengagement of entrained particles from the overhead gas

stream. The solid reactant (zinc concentrate) enters at the left, and solid product leaves

at the right. Product gas, with some carryover solid, leaves at the top right (to proceed

to a cyclone for further removal of solid particles from the gas). The “coils” in the bed

are for a heat exchanger to control T.

Design aspects of fluidized-bed reactors are considered in Chapter 23.

11.2.5 Other Types of Reactors

There are many other reactors of various types not included among those discussed

above. These include tower reactors (Chapter 24), which may be modeled as PF or

modified PF reactors. We describe one further example in this section.

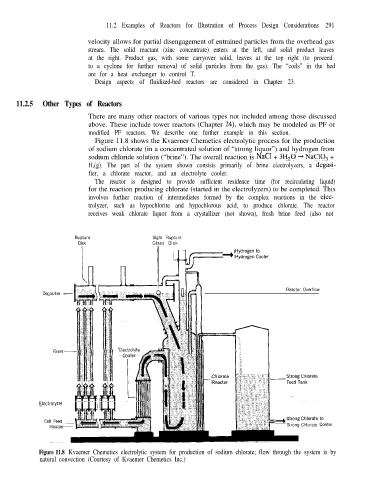

Figure 11.8 shows the Kvaerner Chemetics electrolytic process for the production

of sodium chlorate (in a concentrated solution of “strong liquor”) and hydrogen from

sodium chloride solution (“brine”). The overall reaction is NaCl + 3H,O + NaC103 +

H,(g). The part of the system shown consists primarily of brine electrolyzers, a degasi-

fier, a chlorate reactor, and an electrolyte cooler.

The reactor is designed to provide sufficient residence time (for recirculating liquid)

for the reaction producing chlorate (started in the electrolyzers) to be completed. This

involves further reaction of intermediates formed by the complex reactions in the elec-

trolyzer, such as hypochlorite and hypochlorous acid, to produce chlorate. The reactor

receives weak chlorate liquor from a crystallizer (not shown), fresh brine feed (also not

Rupture Sight Rupture

Disk Glass Disk

Degasifier - Reactor Overflow

Electrolyzel

Cell Feed

Strong Chlorate COI sler

Figure 11.8 Kvaemer Chemetics electrolytic system for production of sodium chlorate; flow through the system is by

natural convection (Courtesy of Kvaemer Chemetics Inc.)